We talked about turning in a previous article explaining what it is, how it works and and which machines are used in this type of processing. Now we want to discuss the different types of processing possible with turning.

Vertical turning:

Vertical turning is a particular process where the lathe is rotated at 90 degrees and the workpiece is held vertically; this allows the headstock to sit on the floor and the faceplate to become a horizontal rotating table, analogous to a huge potter’s wheel. This is useful for the handling of very large, heavy, short workpieces.

This type of processing is recommended when the dimensions of the object make it difficult to install it horizontally and therefore allows the creation of large components. Vertical turning is also used to make round pieces in large quantities.

Tornitura CNC:

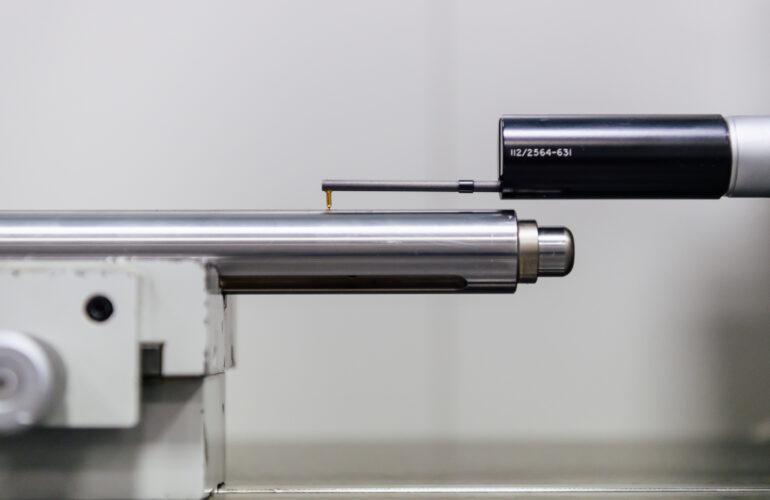

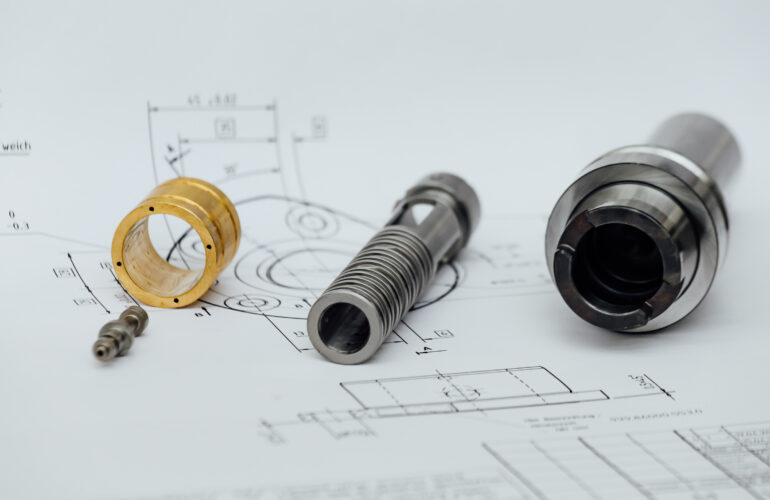

CNC turning (acronym for Computer Numerical Control), is a process that takes place as in a normal lathe but with process entirely automated by a computer.

In CNC turning the metal bar is placed on the spindle of the numerically controlled lathe, while a special tool works to remove the material and to create the desired shapes.

The lathe quickly manufactures the parts by using automated tools. In numerical control turning everything is automated, the operator in fact simply enters the project data in the processing software and intervenes only in case of malfunctions or breakdowns.

The advantages of this process are the very high precision and repeatability of the process, factors that make this process ideal for mass production.

Multi-spindle turning:

Multi-spindle turning is an automated process that allows the processing of different components at the same time. In order to function, a multi-spindle turning requires the head to house several piece-holder spindles that rotate at different speeds, thus processing several different pieces simultaneously and exponentially increasing the processing speed.

At CpGrinding Srl we are specialised in precision mechanical machining for third parties. Contact us for more information

+39035940042