The circular economy is gaining increasing importance in the global industrial landscape, and the precision mechanics sector is no exception. This innovative approach to production and consumption aims to reduce waste, optimize resource use, and reduce environmental impact, all of which have a profound impact on the production of mechanical components.

Circular economy in numbers

By 2030, the circular economy could generate $4.5 trillion in value and create 100 million new jobs globally (source: Ellen MacArthur Foundation).

The European manufacturing industry has the potential to reduce material consumption by 20% by 2030 through the adoption of circular models (source: European Environment Agency).

What is the circular economy?

The circular economy differs from the traditional linear approach of production and consumption, which involves resource extraction, production, use, and final disposal. In contrast, the circular economy aims to keep materials and products in circulation for as long as possible, minimizing waste and maximizing their value.

Impact on the precision mechanics industry

The adoption of circular economy principles is leading to significant changes in the precision mechanics industry:

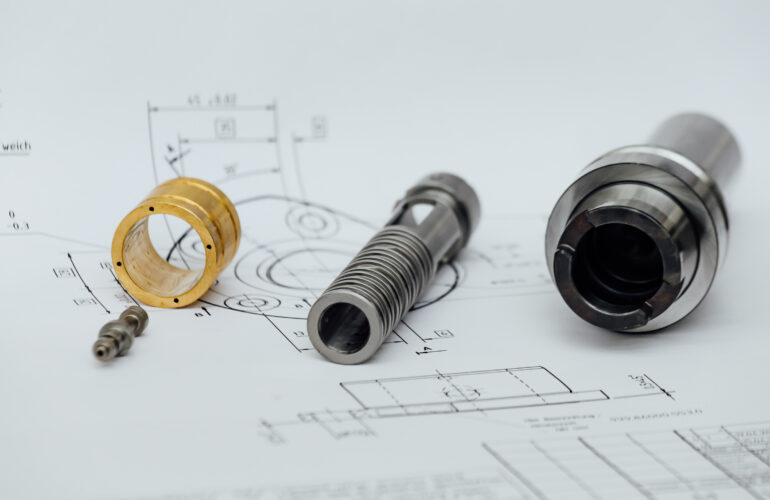

- Design for recyclability and durability: companies are reviewing their design processes to ensure that components are easily recyclable and have a longer life. This requires the use of recyclable materials and the design of modular products that can be disassembled and repaired.

- Regeneration and repair: instead of replacing entire components, companies are investing in the regeneration and repair of existing components. This not only reduces costs and environmental impact, but also promotes a more circular economy.

- Research into sustainable materials: companies are actively seeking more sustainable and environmentally friendly materials for their components. This includes using recycled or biodegradable materials and reducing reliance on non-renewable resources.

Challenges and opportunities for companies

Adopting the circular economy requires a change in mindset and investment in innovation. Companies must:

- Address the challenge of designing recyclable and durable components while maintaining high performance standards.

- Develop new skills and collaborate with partners throughout the value chain to create a circular ecosystem.

- Invest in digital technologies for product traceability and efficient management of material flows.

The circular economy offers multiple benefits for both companies and the environment. In precision mechanics, adopting this approach can lead to greater operational efficiency, reduced costs, and reduced environmental impact. However, success depends on the commitment and collaboration of all stakeholders in promoting more sustainable production and consumption.

CpGrinding is committed to adopting a sustainable production approach that aligns with our values of protecting the environment and resources.