With the term “Industry 4.0”, also known as the fourth industrial revolution, we refer to the trend of industrial automation that integrates new technologies to improve working conditions, create new business models and increase the productivity and production quality of factories.

Industry 4.0 has as its protagonist the use of enabling technologies within the production plant or the use of intelligent machines, interconnected and connected to the internet.

The enabling technologies characterizing Industry 4.0 are:

- Advanced Robotics: Interconnected and rapidly programmable collaborative robots

- Additive manufacturing: 3D printers connected to digital development software

- Augmented reality: Augmented reality to support production processes

- Horizontal / vertical integration: Integration of information along the value chain, from supplier to consumer

- Simulation: Simulation between interconnected machines to optimize processes

- Industrial Internet: Multidirectional communication between production processes and products

- Cloud: Management of large amounts of data on open systems

- Cyber-Security: Security during operations on the network and on open systems

- Big Data and analytics: Analysis of a large database to optimize products and production processes.

The benefits of Insutry 4.0

L’avvento dell’Industria 4.0 si traduce in numerosi benefici:

- Flessibilità: maggiore flessibilità attraverso la produzione di piccoli lotti ai costi della grande scala

- Velocità: maggiore velocità dal prototipo alla produzione in serie attraverso tecnologie innovative

- Produttività: maggiore produttività attraverso minori tempi di set-up, riduzione errori e fermi macchina

- Qualità: migliore qualità e minori scarti mediante sensori che monitorano la produzione in tempo reale

- Competitività del prodotto: maggiore competitività del prodotto grazie a maggiori funzionalità derivanti dall’Internet delle cose

The advent of Industry 4.0 translates into numerous benefits:

- Flexibility: greater flexibility through the production of small batches at large scale costs

- Speed: faster speed from prototype to mass production through innovative technologies

- Productivity: higher productivity through shorter set-up times, reduced errors and downtime

- Quality: better quality and less waste thanks to sensors that monitor production in real time

- Product competitiveness: greater product competitiveness thanks to greater functionality deriving from the Internet of Things

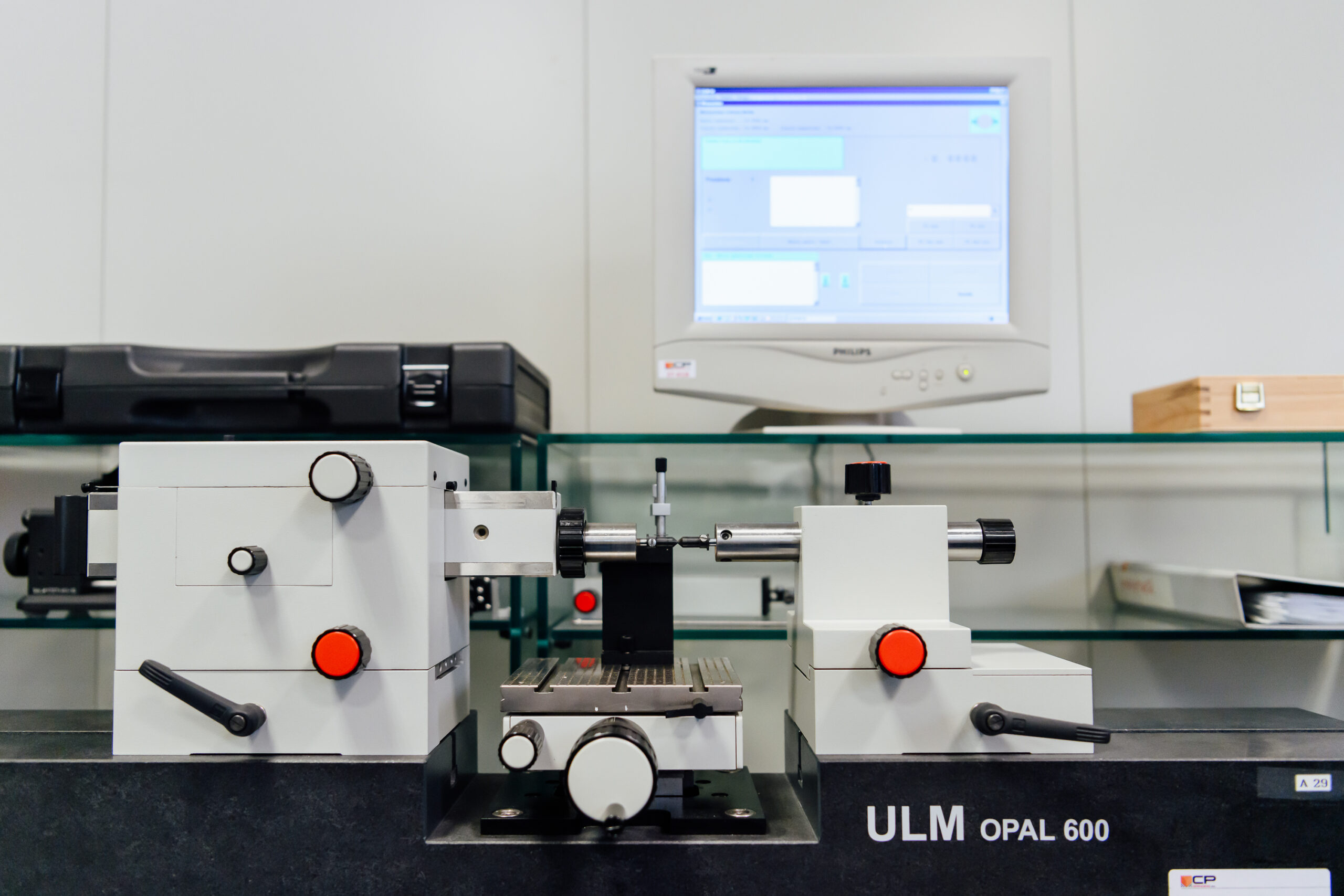

Industry 4.0 and precision mechanics

There is no doubt that the development of Industry 4.0 has had and will continue to have a significant impact on the precision mechanics sector as well.

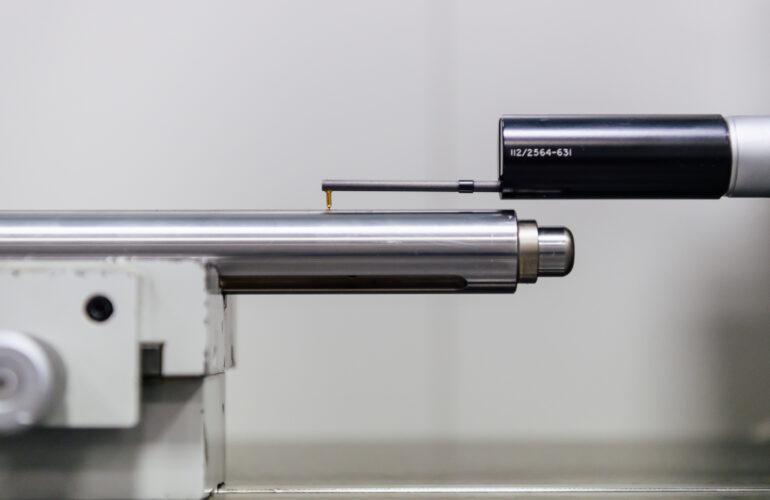

The development reached by technologies will contribute to increase the productivity of this sector and improving the final product, leading to ever greater precision in the achievable results.

In the very near future, factories and workers will be interconnected so as to improve production capacity, efficiency, safety and operational continuity. The pivot of this progress will be the enabling technologies that impact on all industrial processes.

Industry 4.0 is based on the concept of smart factory, i.e. all those processes that represent the heart of manufacturing such as production, internal and external logistics, maintenance, quality and safety, which consists of three parts:

- Smart production: production technologies that create collaboration between all the elements present in the production, i.e. operator, machines and tools

- Smart service: all the IT and technical infrastructures that allow systems to be integrated but also the structures that allow companies to integrate with external structures

- Smart energy: more performing systems capable of reducing energy waste according to the typical paradigms of sustainable energy

For the precision mechanics sector, Industry 4.0 makes it possible to improve the exchange of information by making it accessible to everyone in real time through a simpler and faster process.

The traceability of the processes also increases since, thanks to new technologies, it is always possible to know, throughout the processing cycle, in which processing phase the machines and operators are located. This allows the actual processing, preparation, assembly and testing times to be summarized in a specific and precise way.

With Industry 4.0 it is also possible to monitor the operation of each component of the production chain, thus obtaining better control over production costs.

**

As a company operating in the precision mechanics sector, we have always paid close attention to the technological developments so as to be able to offer our customers only the best of Made In Italy production thanks to the increasingly close connection between the know-how of our human capital and a constantly evolving machine park.

Contact us for more information.