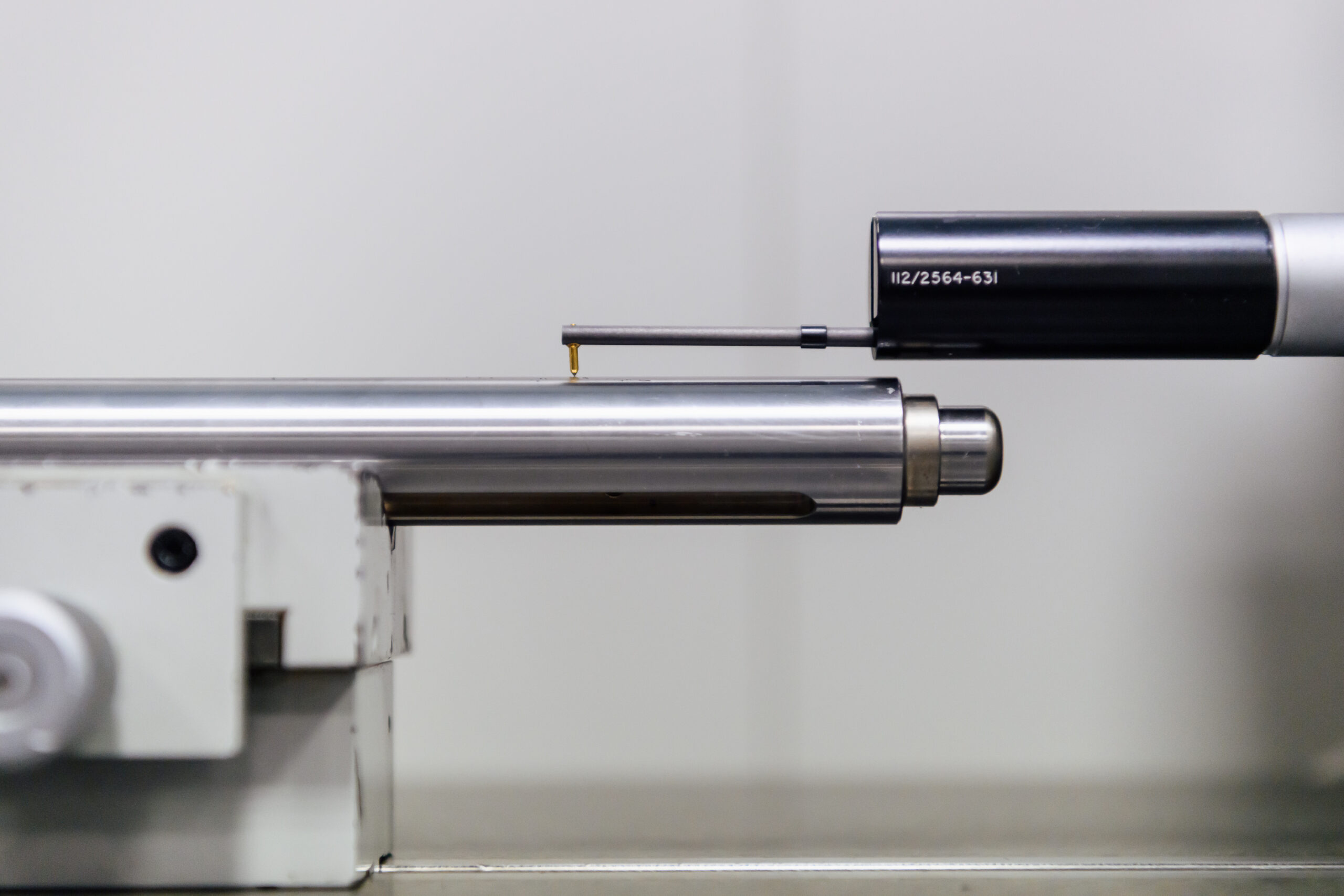

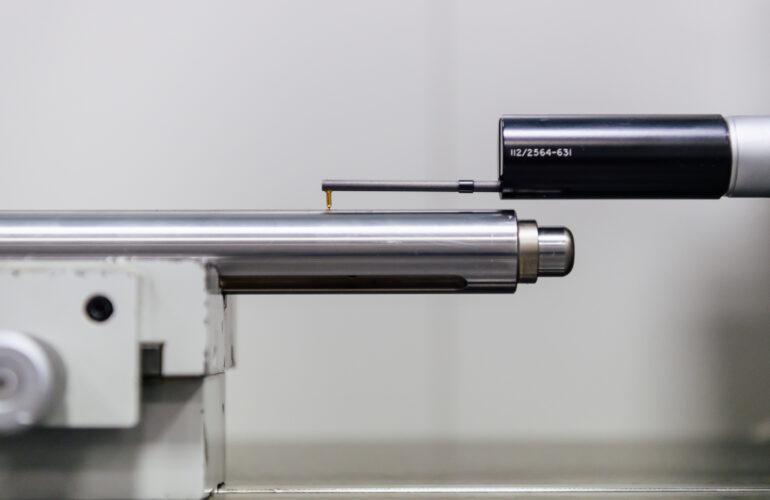

In precision mechanics, high-speed balancing is a crucial aspect to ensure the proper functioning of machinery, rotors, and rotating components. High rotational speeds can generate vibrations, centrifugal forces, and asymmetric loads, which can adversely affect the performance, lifespan, and safety of moving systems.

The importance of high-speed balancing

High-speed balancing aims to minimize unwanted vibrations and reduce the negative effects caused by the imbalance of rotating components. These components can include shafts, rotors, blades, discs, and other elements that rotate at high speeds. Proper balancing helps ensure an even distribution of mass and stable rotation, reducing wear, vibrations, and energy dissipation.

The lack of proper balancing can lead to serious consequences, such as damage to bearings, seals, surrounding structures, and even catastrophic failures of rotating components. Therefore, high-speed balancing techniques are essential to ensure reliable performance and safety in applications where high speeds are reached.

Methods of High-Speed Balancing

There are several methods used for high-speed balancing in precision mechanics. These include:

- Static balancing: This method involves adding or removing material from the rotating components to achieve an even mass distribution. It is performed using precision tools such as grinders or milling machines to make targeted modifications.

- Dynamic balancing: This technique entails measuring the imbalance forces during the operation of the high-speed rotating system. These measurements are used to determine the location and amount of material to be added or removed to achieve optimal balance.

- Two-plane balancing: This method involves dividing the rotating component into two balancing planes. Additional masses are applied at specific positions on each plane to reduce the effects of imbalance.

- Automatic balancing: Some advanced systems utilize electronic or electromechanical devices to monitor and automatically adjust the balance during operation. These systems can make real-time modifications to maintain precise balance even under varying conditions.

Advantages of High-Speed Balancing

High-speed balancing offers numerous advantages in precision mechanics. Some of the key benefits include:

- Vibration and wear reduction: Proper balancing reduces vibrations and wear on rotating components, thereby increasing their lifespan and reliability.

- Performance improvement: By reducing the effects of imbalance, stable operation and increased efficiency of machinery and rotating systems can be achieved.

- Enhanced safety: By reducing vibrations and negative effects of imbalance, the risk of catastrophic failures and damage to surrounding structures is minimized.

Conclusion

In precision mechanics, high-speed balancing is crucial to ensure reliable performance, longevity, and safety of rotating components. The use of high-speed balancing techniques, such as static and dynamic balancing, helps minimize unwanted vibrations and optimize the operation of high-speed moving systems. Adopting these balancing practices contributes to the reliability, lifespan, and efficiency of rotating components in precision mechanics.