Lapping is a machining process performed on a metal, ceramic or glass surface, to minimize its roughness. The exact definition given by dictionaries: ” Lapping is a machining process, in which two surfaces are rubbed together with an abrasive between them, by hand movement or by way of a machine. “.

In precision mechanics, lapping is performed on steel after the hardening treatment. This process is commonly carried out for molds for plastic materials, obtaining very shiny and transparent products. Lapping is also used for molds for the production of household items.

How does lapping work:

The first type of lapping, usually called grinding, involves rubbing a brittle material such as glass against a surface such as iron or glass itself, known as the grinding tool, with an abrasive such as aluminum oxide, jeweller’s rouge, optician’s rouge, emery, silicon carbide, diamond, etc., between them. This produces microscopic conchoidal fractures as the abrasive rolls about between the two surfaces and removes material from both.

The other form of lapping involves a softer material such as pitch or a ceramic for the lap, which is “charged” with the abrasive. The lap is then used to cut a harder material—the workpiece. The abrasive embeds within the softer material, which holds it and permits it to score across and cut the harder material. Taken to a finer limit, this will produce a polished surface such as with a polishing cloth on an automobile, or a polishing cloth or polishing pitch upon glass or steel.

What is a lapping machine

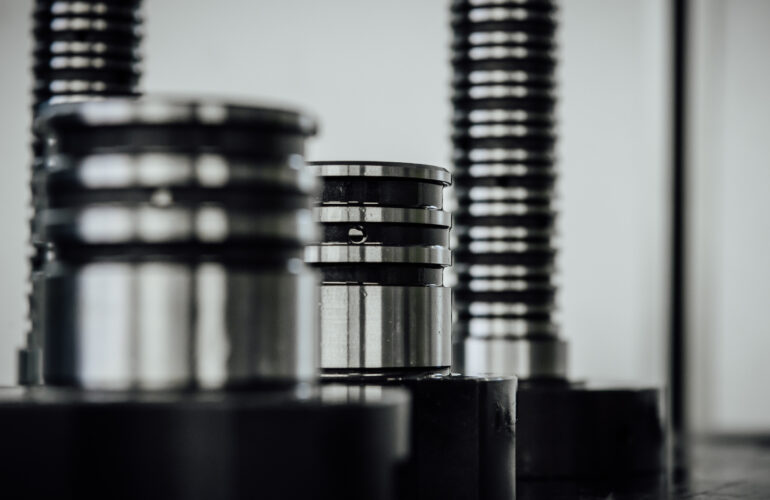

The lapping machine is an industrial machine available in different shapes and sizes depending on the needs of use. The compact and portable lapping machines are used for lapping particularly small pieces, such as precision mechanisms and jewelery. Medium and large-sized lapping machines process pieces and surfaces of larger dimensions. The lapping machines can also be horizontal or vertical.

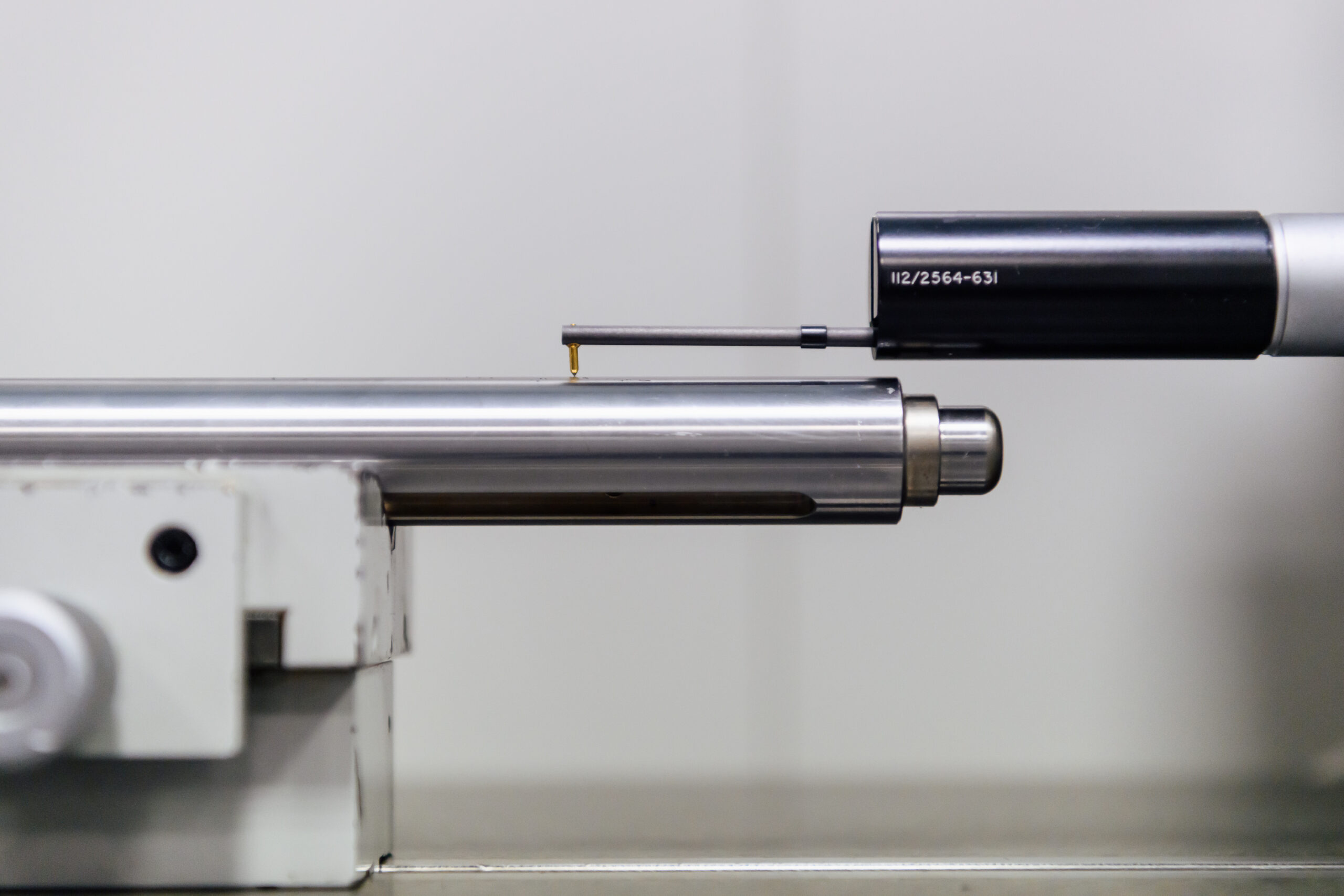

The operation of the lapping machine is based on a shaft placed inside the machine in which brushes are housed to work the surfaces of the pieces. The shaft acts by rotating around its own axis, exerting pressure on the workpiece so as to smooth out any irregularities and obtain the desired results.

**

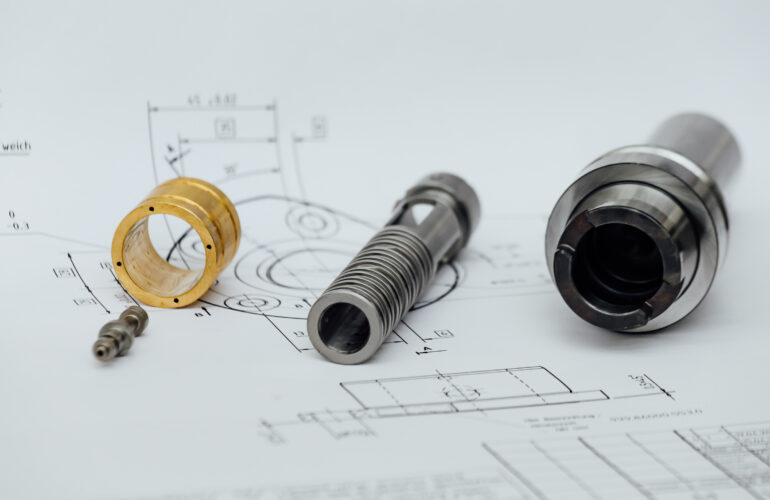

As a company we deal with the machining of mechanical parts that require a high standard of precision both in the design and construction phases. Contact us for more information.

+39 035 940042