Blockchain technology is revolutionizing numerous industries, including component traceability, by providing a secure, transparent, and reliable solution for managing and recording information.

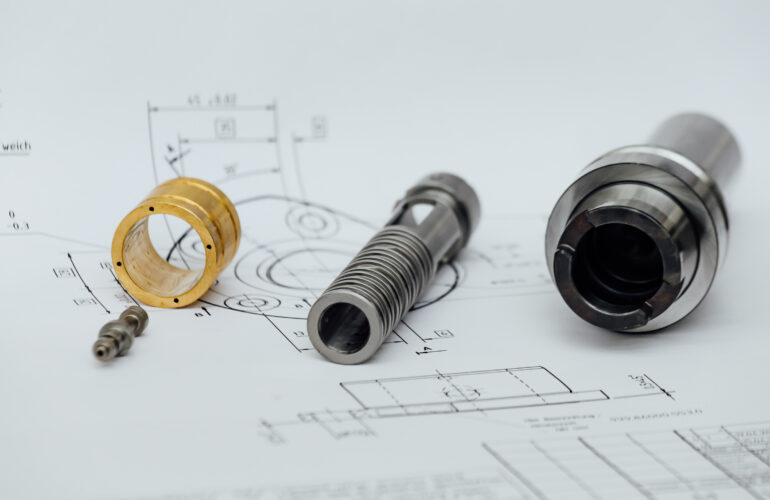

In the context of precision mechanics, the implementation of blockchain technology can ensure accurate traceability of components throughout the entire production and supply chain.

Here are some key points related to the impact of blockchain technology on component traceability:

- Transparency and data integrity:

Blockchain is a decentralized and secure network that records transactions permanently and immutably. This ensures data integrity by preventing unauthorized modification of information about individual components.

In the precision mechanics production chain, blockchain can be used to record information such as serial number, origin, technical specifications, and quality testing of components. This information can be accessible to all participants in the production chain, ensuring transparency and data integrity.

For example, an aerospace components manufacturer can use blockchain to record information about each component, such as serial number, material used, technical specifications, and quality test results. This information can be used by aircraft manufacturers to ensure that components meet safety requirements.

- Component traceability:

Each component can be associated with a unique cryptographic transaction on the blockchain, allowing for the recording of the entire journey, from origin to destination. This facilitates the identification of the origin and authenticity of components.

For example, a machinery components manufacturer can use blockchain to track each component along the production chain. This can help identify components that may have been damaged or do not meet quality requirements.

- Reduced risk of fraud:

The immutable traceability offered by blockchain reduces the risk of counterfeiting and fraud, increasing confidence in the quality and authenticity of components.

For example, an automotive components manufacturer can use blockchain to record information on production data and quality testing. This information can be used to identify counterfeit or defective components.

Additional examples of how blockchain can be used to improve component traceability in the precision mechanics industry

Blockchain can be used to record information about the lifecycle of components, such as maintenance activities and failures. This can help identify components that are approaching the end of their useful life and plan for replacement proactively.

Maintenance activities and failures

Blockchain can be used to track the performance of components over time. This can help identify components that may no longer meet safety or quality requirements.

Component performance over time

Blockchain can be used to create a secondary market for components. This can help reduce waste and improve the efficiency of the supply chain.

Data and statistics

According to a Gartner report, the global market for blockchain-based component traceability is expected to reach $2.5 billion by 2025.

Another report, from IDC, estimates that blockchain will be used by over 60% of manufacturing companies by 2023.

These data indicate that blockchain technology is rapidly becoming a standard solution for component traceability.

The implementation of blockchain technology in the precision mechanics production chain can significantly improve component security and traceability. Blockchain offers a secure, transparent, and reliable solution for managing and recording information, which can help reduce fraud risks and improve customer satisfaction.