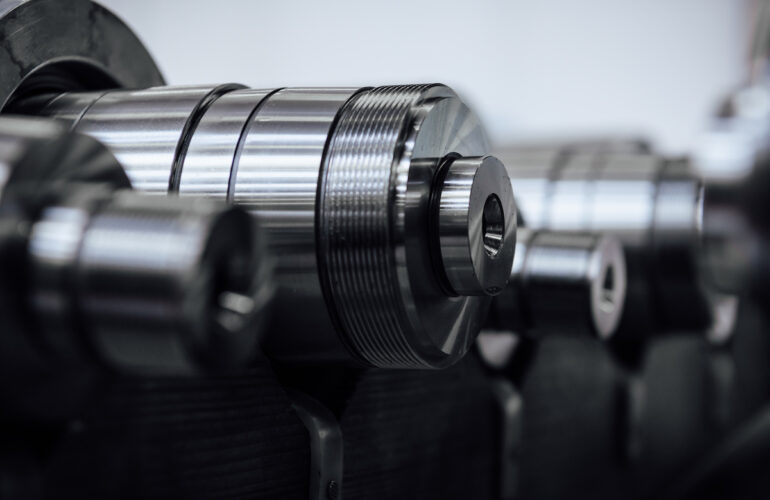

Precision mechanics deals with the design and production of mechanical parts that require a high standard of precision, both in the design phase and in the construction phase.

Precision mechanics is used in different fields and applications. Many products that use precision mechanical components also operate in difficult conditions, which makes the quality and integrity of the product of prime importance. In fact, precision mechanics is not only used in electronic innovations designed to push the boundaries of technology but to improve common items in current technologies to make them more efficient and meet the needs of today’s consumer.

This flexibility of the various precision engineering applications offers companies new capabilities and services that enable them to compete in established markets and engage in the development of future markets.

Within our company we have highly specialized professionals such as threader, workshop manager and mechanical engineer.

- Workshop manager: carries out strategic coordination activities of the various production phases, takes part in the assembly line and supervises quality control. He is the reference of the production department with over 30 years of experience in the sector.

- Mechanical engineer: our mechanical expert is a grinding operator, quality control manager of the company and reference point in the metrology room. The alternation between grinding activities and quality control allows him to have a broader and more detailed view of the entire production process.

Thanks to the years of experience of our team, we are able to offer our customers innovative products with an accelerated time-to-market. At CpGrinding we are able to combine design, material, compliance and manufacturing expertise to build components for different industries with rigorous mechanical specifications.

Contact us for more information.