Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.

Turning is defined by a rotary motion of the piece, which is fixed to a spindle, and a rectilinear motion; the cutting edge of the tool penetrates the piece (that can be metal or other materials) removing the excess part and giving it the desired shape.

In precision metal processing, turning is a widely used technique and, depending on the type of surface you want to obtain, is divided into:

- Tapered turning: it produces a cylindrical shape that gradually decreases in diameter from one end to the other. This can be achieved from the compound slide, from taper turning attachment, using a hydraulic copy attachment or using a C.N.C. lathe.

- Spherical generation: it produces a spherical finished surface by turning a form around a fixed axis of revolution. Methods include using hydraulic copy attachment, C.N.C. and using a form tool.

- Hard turning: it is a type of turning done on materials with a Rockwell C hardness greater than 45. It is typically performed after the workpiece is heat treated. The process is intended to replace or limit traditional grinding operations.

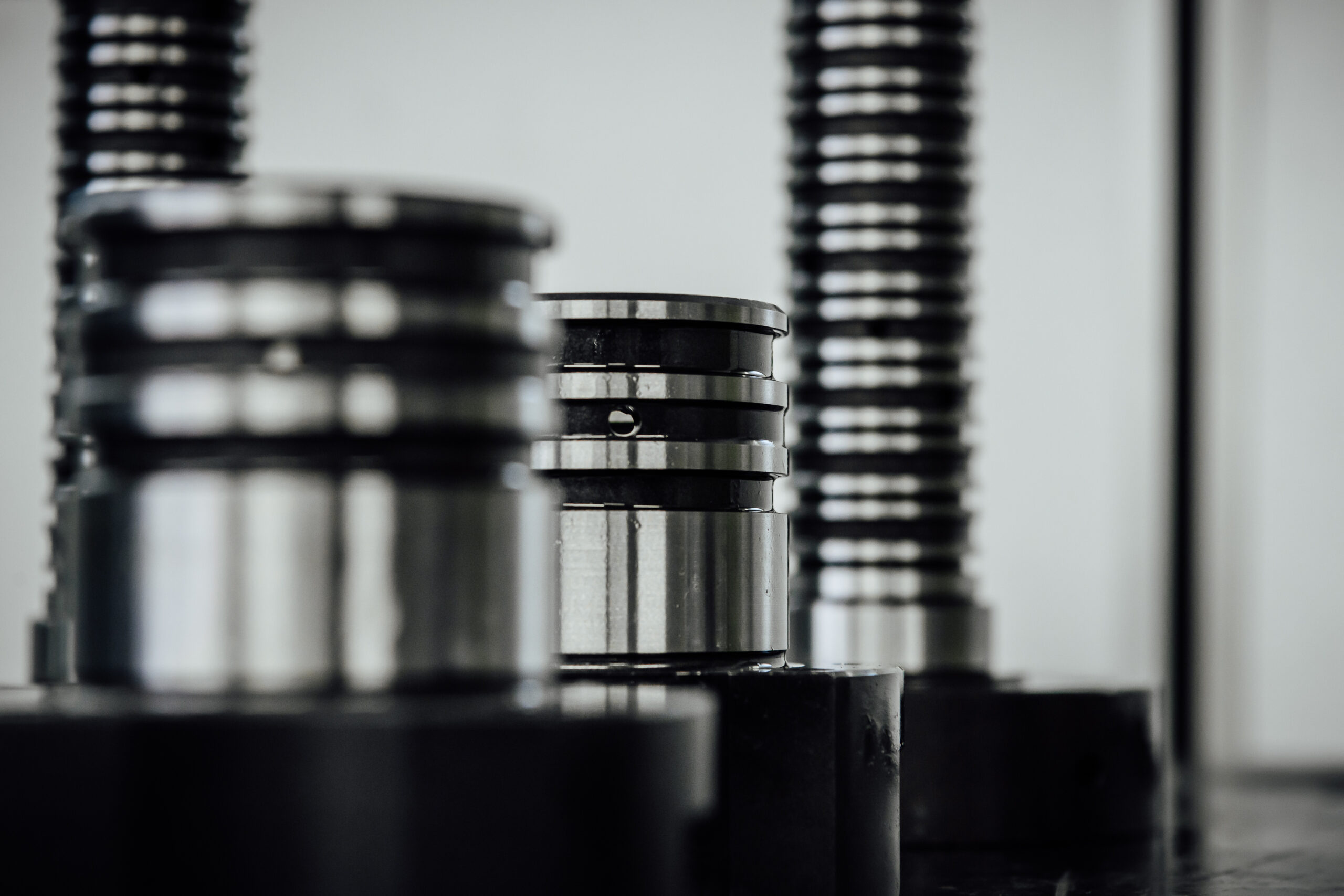

Machinery for precision mechanical turning

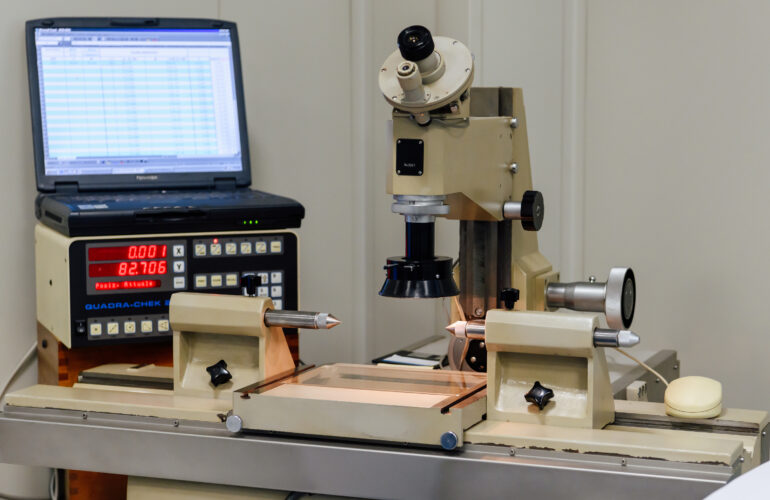

In the past, turning was performed using manually operated machinery. Nowadays, thanks to the most modern technologies, turning is performed using numerically controlled machinery, that is automatic lathes. These machines execute the instructions given by a computer, thus making pieces of very high precision.

Technologies such as Cad-Cam allow you to program the machine to perform predetermined and controlled movements and to carry out specific and even very complex projects in a very short time.

In mechanical turning processes, it is necessary to set parameters that vary according to the metal to be processed, the material and size of the tool used in order to obtain the desired processing.

At CpGrinding are a company specializing in precision turning, thanks to the know-how of our operators and the latest generation machines we have, and we can guarantee our customers maximum accuracy in processing and finishing the product as well as speed in processing. Contact us for more information