When we talk about grinding operationswe often hear about Big Plus, but what exactly does it mean?

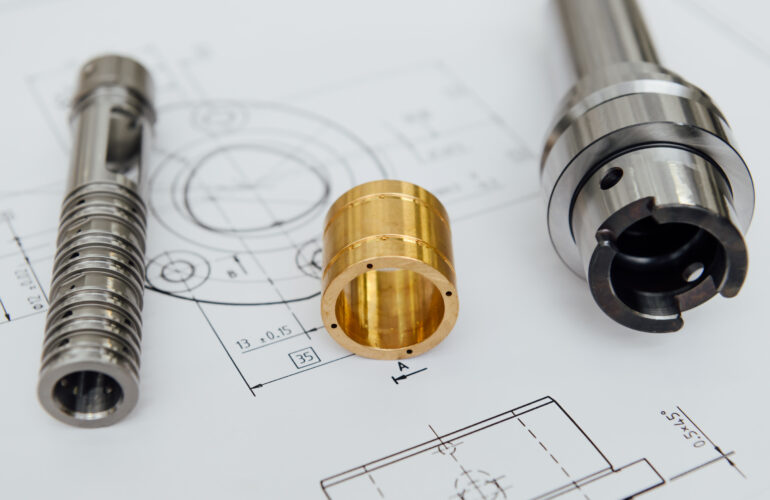

The BIG-PLUS Spindle System offers simultaneous dual contact between the machine spindle face and toolholder flange face, as well as the machine spindle taper and long toolholder taper shank. This system is based on the most currently available standards for JIS-BT, DIN69871 and CAT-V Flange tooling.

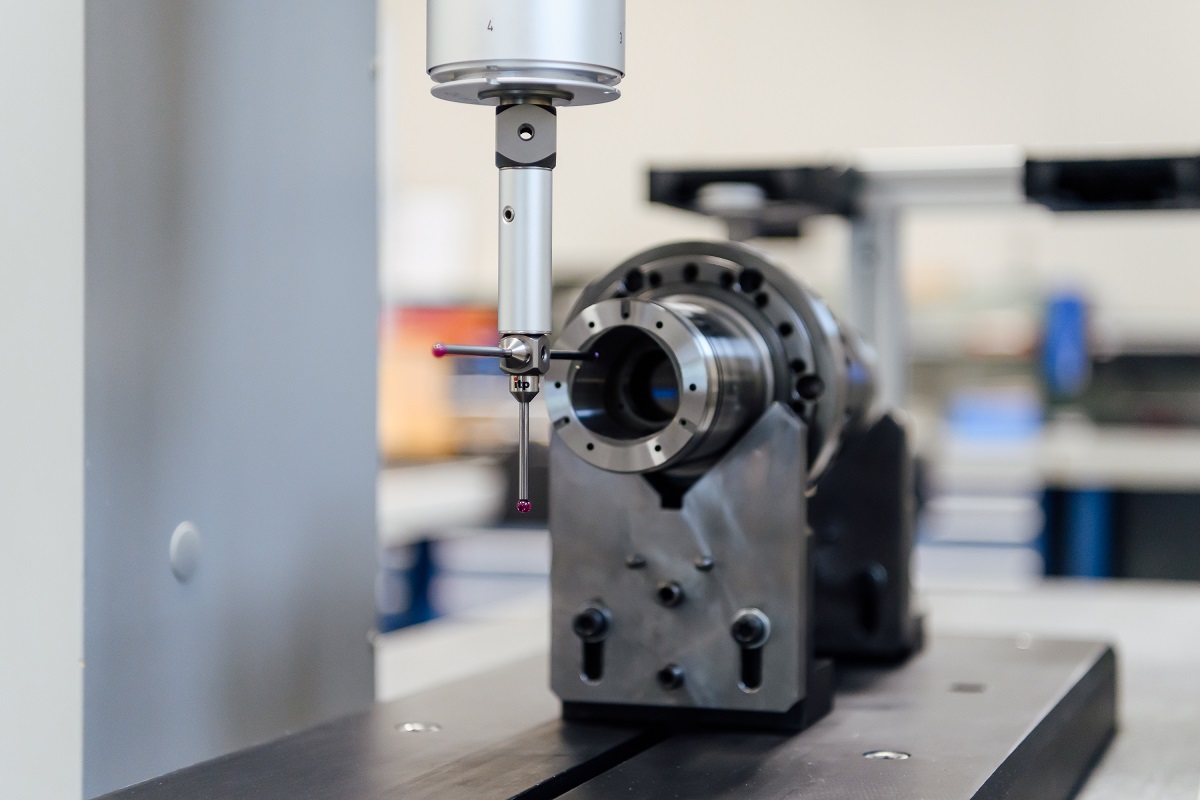

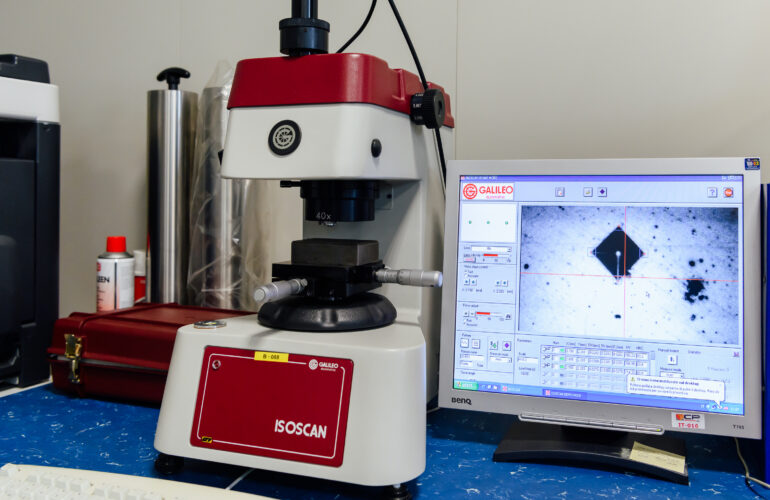

he BIG-PLUS Spindle System strictly dictates the dimensions of the spindle face of a machine and the flange face of a toolholder. These dimensions are controlled by exclusive high tolerance gauges and measuring equipment, so dual contact of the taper and face is guaranteed. Full interchangeability therefore exists between all BIG-PLUS machine spindles and BIG-PLUS toolholders.

The advantages of BIG-PLUS:

- Rigidity improvement thanks to an increased fit diameter

- Drastic improvement of the ATC repeatability

- Prevention of displacement in the Z-axis

- Improvement of the life of the cutting tool

- Prevention of fretting corrosion

- Improvement and stability of the machining accuracy and machined surface

Big Plus is a registered trademark and we at CpGrinding Srl are in possession of the license for the construction of Big Plus cone-flat cones of the Japanese Big Diashowa.