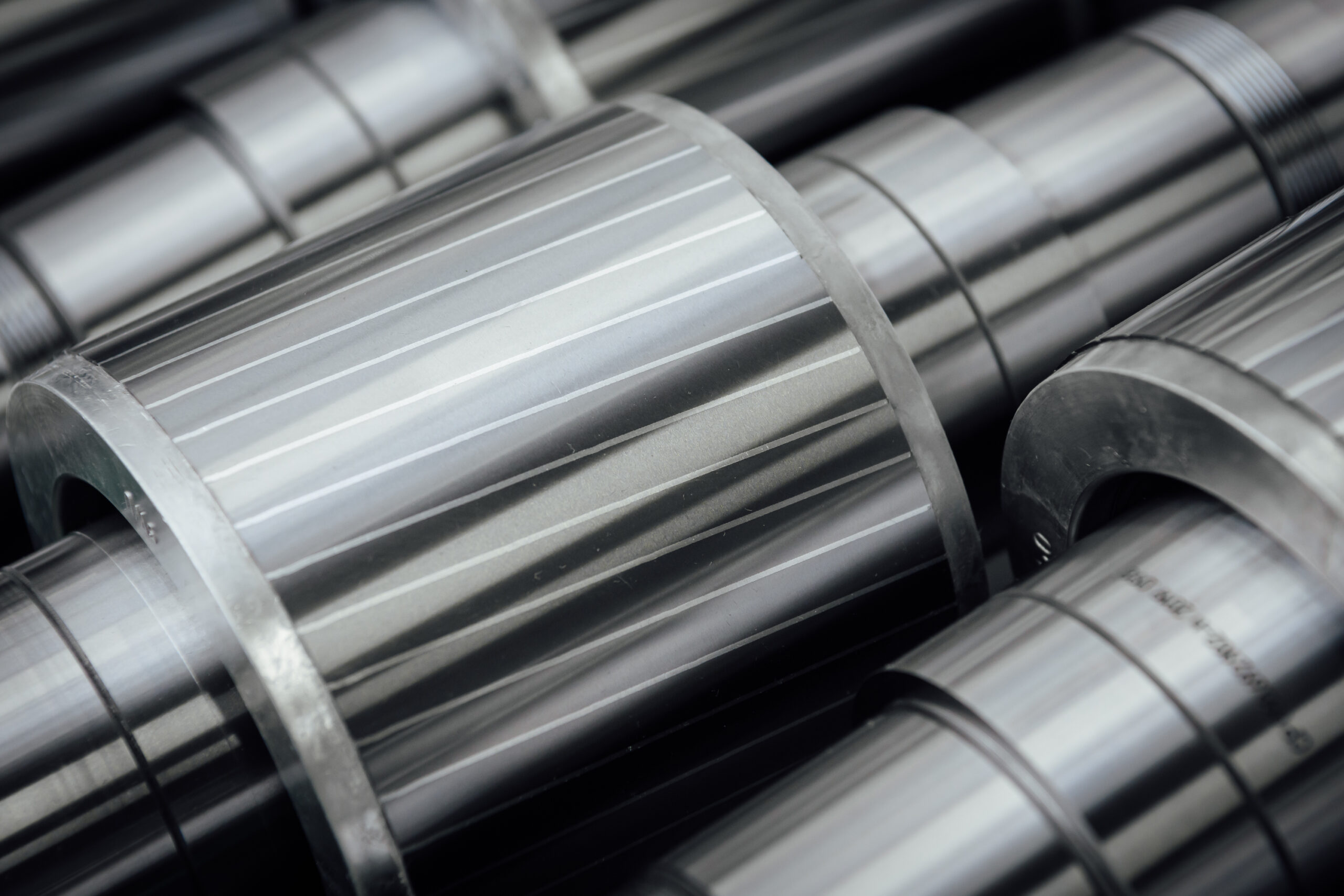

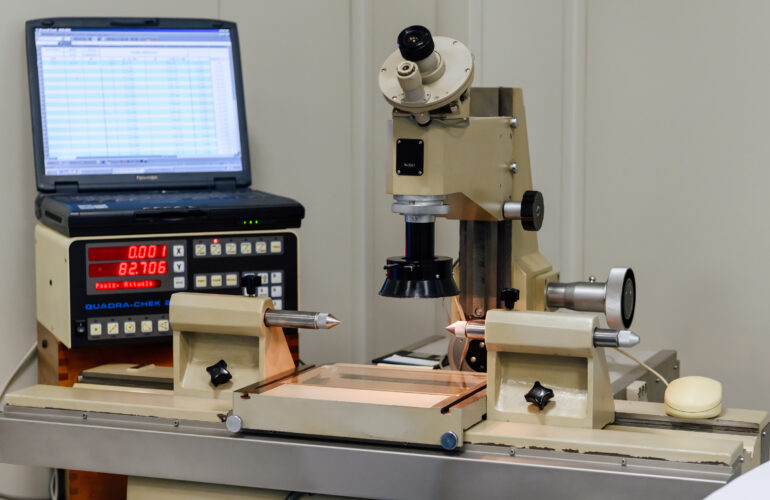

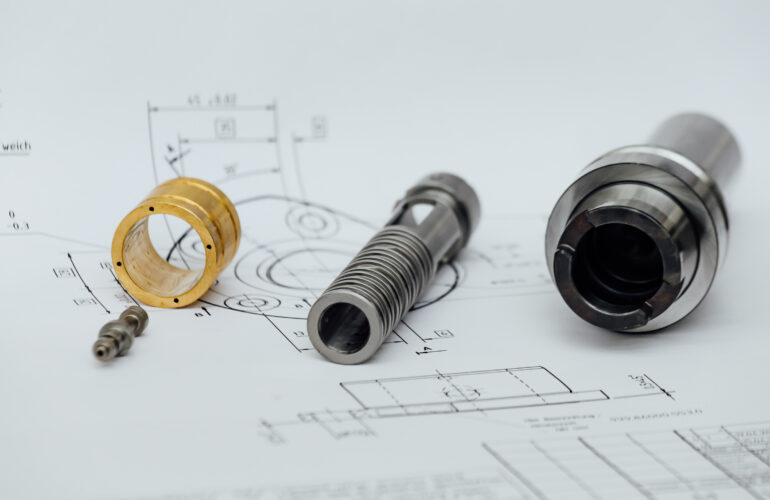

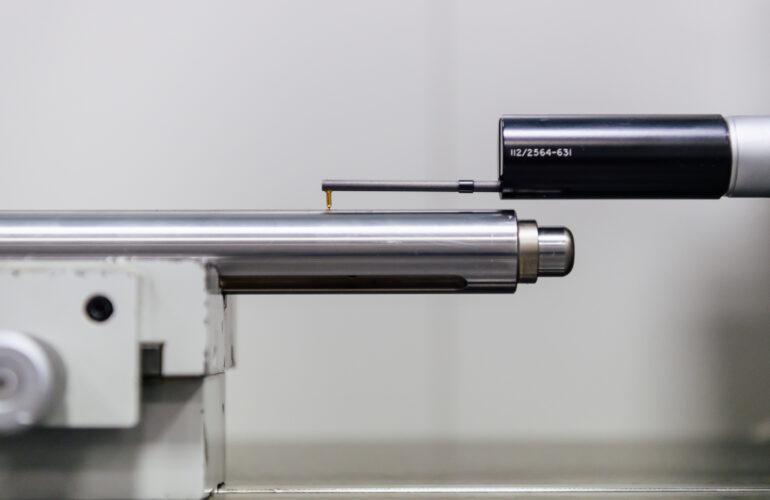

Precision mechanics is an advanced discipline that uses tools and techniques to produce components and parts with extremely tight tolerances, ensuring maximum precision in measurements and surface finishing.

This discipline offers numerous advantages for production, including:

- Better product quality: thanks to extreme precision, precision mechanics allows for the production of components that meet required specifications, minimizing errors and deformations of parts. This results in high-quality final products and greater customer satisfaction.

- Reduction of production costs: adopting precision mechanics reduces waste and production defects, minimizing overall production costs. Additionally, due to the precision of processing, processing times and material losses are reduced, further reducing costs.

- Greater production flexibility: precision mechanics makes it possible to produce parts and components with complex designs and geometries that would be difficult or even impossible to produce with other technologies. This allows for greater production flexibility and the ability to customize products based on customer needs.

- Increased durability and reliability: due to the precision of processing and reduced errors, components produced with precision mechanics are generally more durable and reliable than those produced with other technologies. This translates into greater safety for end-users of the products.

In summary, the use of precision mechanics in production offers numerous advantages, including improved product quality, reduced production costs, greater production flexibility, and increased durability and reliability of produced components.

Thanks to these features, precision mechanics represents a fundamental resource for companies seeking to improve their competitiveness and offer high-quality products to their customers.