The Internet of Things (IoT) is reshaping production processes across all industries, including precision mechanics. The IoT constitutes a global network of interconnected physical objects, or “things,” capable of collecting and transmitting data to enhance processes, reduce costs, and improve efficiency.

Benefits of IoT integration in precision mechanics

The integration of IoT technologies in machinery and production systems brings forth several advantages, including:

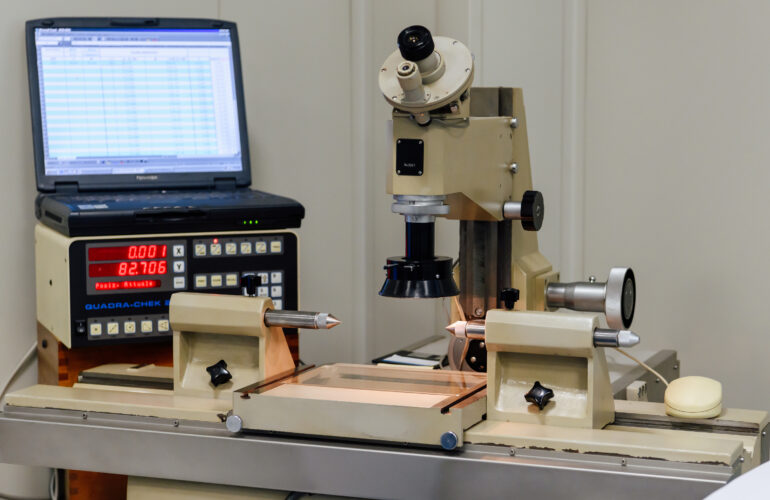

- Advanced Connectivity: IoT facilitates real-time communication and data sharing among machinery, tools, and production systems. This enhances visibility into production processes, enabling more informed decision-making.

- Continuous Monitoring: Intelligent sensors embedded in machinery collect vital data, allowing for detailed monitoring of performance and operational conditions. This aids in identifying potential issues before they occur, reducing downtime and maintenance costs.

- Predictive Maintenance: IoT supports predictive maintenance, enabling the prediction of when a machine might require maintenance. This helps reduce unplanned downtime and enhances operational efficiency.

- Process Optimization: Analysis of data collected by IoT identifies areas for improvement in production processes. This can increase efficiency, reduce costs, and enhance product quality.

- Traceability and Quality: IoT enables accurate traceability of precision components throughout the entire production chain. This is crucial for ensuring quality and responding promptly to any issues.

- Data Security: Data security is a critical aspect of IoT, especially when handling sensitive production information. Companies integrating IoT in precision mechanics must implement appropriate security measures to protect generated data.

Challenges and Solutions

Implementing IoT technologies in precision mechanics may pose challenges, including:

- Costs: The implementation of IoT technologies can require a significant initial investment.

- Skills: Companies integrating IoT in precision mechanics must possess the necessary skills to manage IoT data and applications.

- Security: Data security is a critical concern in IoT, and companies must adopt suitable security measures to protect generated data.

CpGrinding’s example: leading with iot integration

At CpGrinding, we exemplify how IoT integration in precision mechanics can significantly enhance production processes and business outcomes. Through the implementation of IoT technologies, we have successfully reduced machine downtime, improved product quality, and lowered operational costs. Our experience demonstrates that IoT is a strategic technology that can help precision mechanics companies compete in an increasingly competitive market.