Precision mechanics has revolutionized the automotive industry, enabling the design and manufacture of high-performance vehicles that deliver optimal performance, safety, and efficiency.

From engine components to suspension systems, precision mechanics play a critical role in the development and production of many automotive parts and systems.

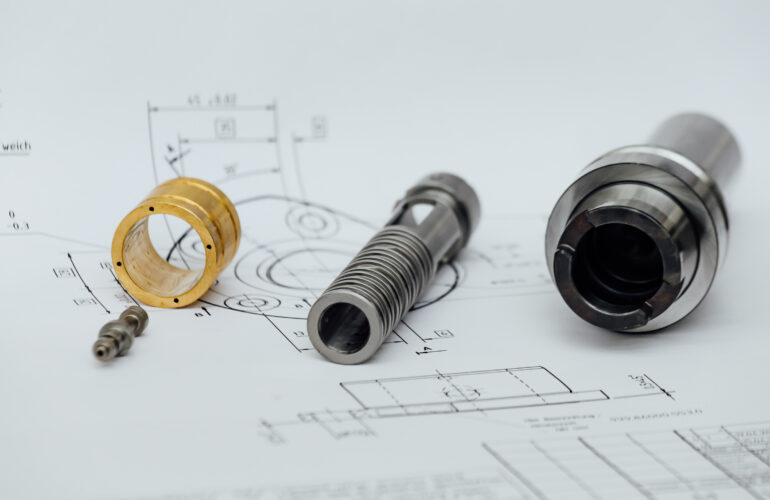

The use of precise machining, measurement, and assembly techniques is essential for ensuring that these components and systems function reliably and efficiently, providing a smooth ride and optimal driving experience.

In this article, we will explore the applications of precision mechanics in the automotive industry, examining how it has enabled the development of advanced engine, transmission, suspension, and braking systems.

Applications of precision mechanics in the automotive industry:

- Engine components: precision mechanics play a crucial role in the design and manufacture of engine components such as camshafts, crankshafts, and pistons. These components require tight tolerances and high precision to ensure optimal performance and reliability.

- Suspension and steering systems: precision mechanics are also used in the design and manufacture of suspension and steering systems. These systems must be able to handle the weight of the vehicle and provide a smooth ride, while also maintaining precise alignment and control.

- Transmission and drivetrain: precision mechanics are critical in the design and manufacture of transmissions and drivetrains, which must deliver power efficiently and reliably while also maintaining precise control over the vehicle’s speed and direction.

- Braking systems: braking systems rely on precision mechanics to ensure that they operate reliably and efficiently. Components such as brake discs and calipers must be designed and manufactured with tight tolerances to ensure that they function properly and provide consistent braking performance.

- Electrical and electronic systems: precision mechanics also play a role in the design and manufacture of electrical and electronic systems in modern vehicles. Components such as sensors, actuators, and motors require precise machining and assembly to ensure optimal performance and reliability.

In summary, precision mechanics play a vital role in the design and manufacture of many automotive components and systems. The use of precise machining, measurement, and assembly techniques is essential for ensuring that these components and systems operate reliably and efficiently, delivering optimal performance and safety for drivers and passengers.

Contact us for more information.