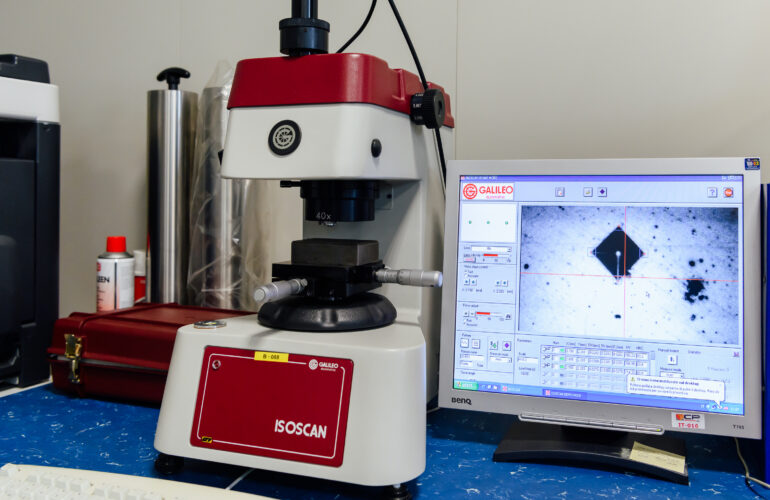

Durometers play a crucial role in precision mechanics for the accurate measurement of material hardness. In the production of high-precision mechanical components, it is essential to know the hardness of the materials used to ensure they meet quality standards and required design specifications.

Quality Control and Material Selection

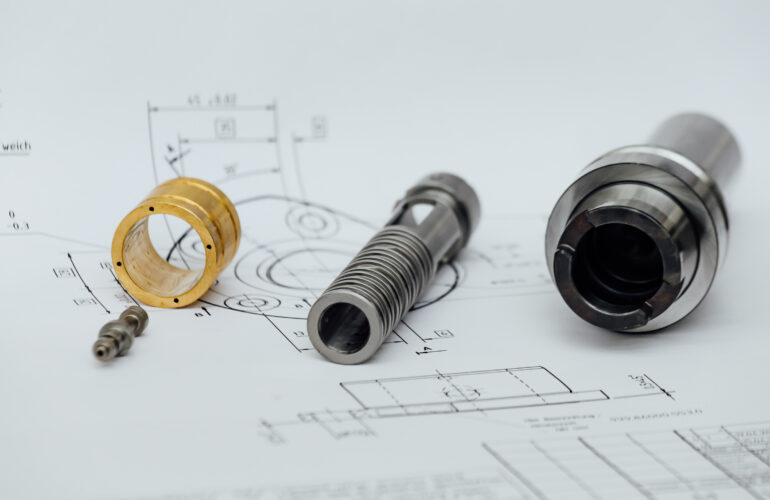

In precision mechanics, the hardness of the materials used can directly impact the strength, durability, and performance of mechanical components. Durometers are employed to measure the hardness of materials such as steel, aluminum, titanium, and other alloys used in the production of precision components.

Quality control is fundamental in the manufacturing of mechanical components, and durometers are indispensable tools for this purpose. By accurately and repeatably measuring the hardness of materials, durometers verify that the materials meet specified hardness standards and design requirements.

Furthermore, durometers play an important role in material selection for precision mechanical components. Choosing materials with the appropriate hardness is crucial to ensure the functionality and reliability of components in the long term. By measuring material hardness during the selection phase, it is possible to identify the most suitable materials to meet desired performance and durability requirements.

Process Control in Machining

Durometers in precision mechanics are also used for process control in machining. During the production of mechanical components, variations in hardness can occur due to heat treatments, mechanical machining, or other machining operations. Durometers allow for monitoring and verification that material hardness remains within specified limits during these critical machining stages.

Process control in machining helps ensure that mechanical components maintain desired properties such as strength, hardness, and durability, enabling consistent and high-quality production.

Durometers play a crucial role in precision mechanics for the accurate measurement of material hardness. They are essential tools for quality control, material selection, and process control in machining. Thanks to durometers, it is possible to ensure that mechanical components meet required quality standards, providing reliable and durable performance