Threading is a critical process in precision mechanics, where quality and accuracy are essential to ensure the reliable assembly and operation of components.

In this article, we will explore best practices for the threading process, including common challenges and solutions to achieve high-level results. We will also present specific examples of work carried out by cpgrinding, a leader in the precision mechanics industry.

The importance of precision threading

Threading is a method for creating threads on surfaces, allowing for the precise interconnection of parts that require very tight tolerances. In precision mechanics, the threading process is crucial because it enables the accurate assembly of components with very fine tolerances.

Best practices for precision threading

- Planning and design: accurate planning is essential for successful threading. Defining thread specifications, tolerances, and materials to use is the crucial first step.

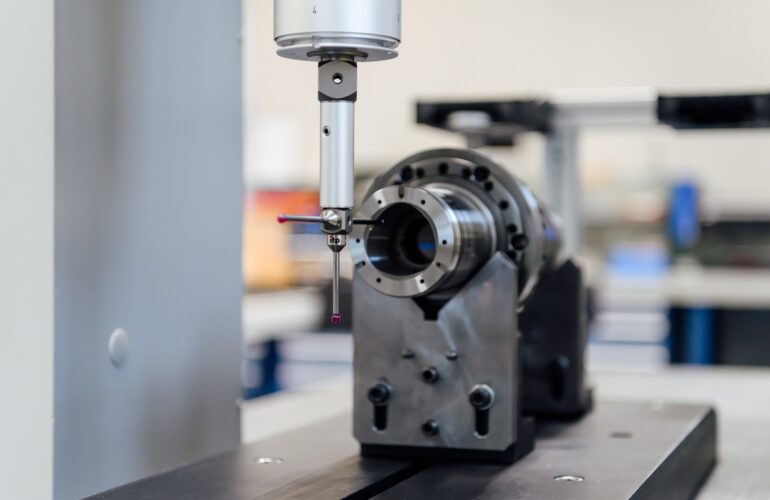

- Tool selection: choosing the right tools is paramount. High-quality and well-maintained tools are essential for achieving precise threads. Cpgrinding employs top-quality precision tools.

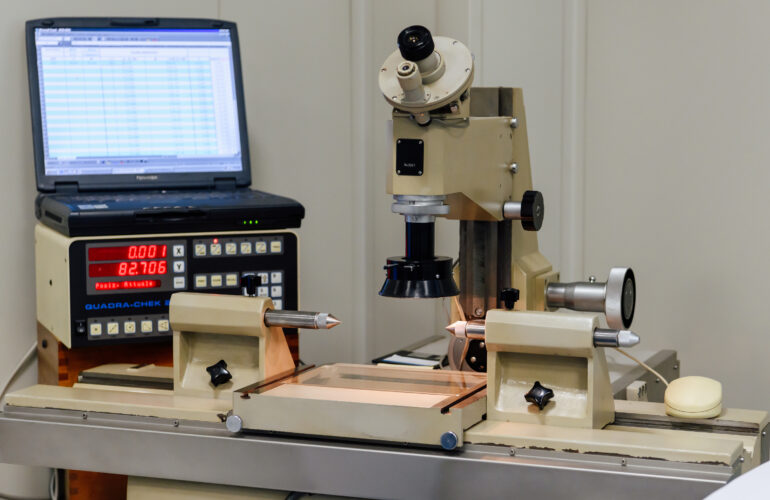

- Tolerance control: maintaining tight tolerances is a key objective in precision mechanics. Precision measuring tools like calipers and micrometers are used to ensure that the threads meet the requirements.

- Proper lubrication: using the appropriate lubricant reduces friction during threading, improving thread finish and extending tool life.

- Real-time quality control: cpgrinding utilizes advanced monitoring systems to verify thread quality in real-time, allowing for immediate corrections if necessary.

Common challenges and solutions

- Tool wear: tool wear is a common challenge. The solution is regular maintenance and timely tool replacement to ensure precise threads.

- Threading defects: threading defects such as burrs or cracks can occur. Proper machine setup and quality monitoring help prevent these issues.

- Different materials: working with different materials requires attention to the specific material properties to achieve quality threads.

Our offer

We specialize in precision threading for critical components in a wide range of industries. From aerospace to automotive, we provide high-precision threading solutions to meet the specific needs of our clients.