The mechanical industry stands as one of the most crucial sectors in the global economy, with a turnover exceeding 2.5 trillion dollars in 2022. In 2023, the industry is poised to continue its growth trajectory but will encounter a set of challenges and opportunities.

Market Trends

One of the key market trends that will influence the mechanical industry in 2023 is the escalating demand for sustainable products and services. Both consumers and businesses are becoming increasingly aware of the environmental impact of products and manufacturing processes, compelling mechanical companies to develop more sustainable products and processes.

Another significant trend is the growing digitization of the sector. The Internet of Things (IoT) technology is becoming increasingly prevalent in mechanical factories, empowering companies to enhance efficiency, reduce costs, and improve product quality.

Technological Innovations

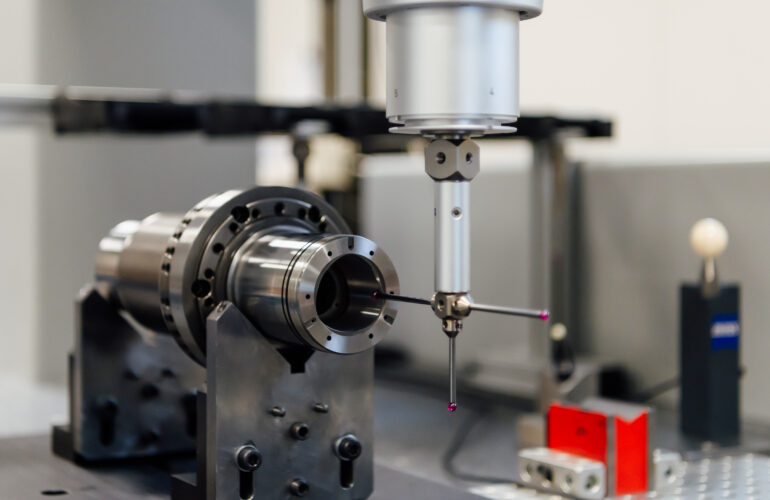

The mechanical industry is in a constant state of innovation, with emerging technologies revolutionizing the way products are designed and developed. Among the most promising technologies are advanced materials, such as lightweight alloys and composite materials, making mechanical products lighter, more robust, and more efficient.

Other noteworthy innovations include advanced manufacturing technologies like 3D printing and collaborative robotics, making production processes more flexible and productive.

Sustainability

Sustainability is a paramount trend that will shape the mechanical industry in 2023. Consumers and businesses are increasingly conscious of the environmental impact of products and manufacturing processes, urging mechanical companies to develop more sustainable products and processes.

Mechanical companies can reduce the environmental impact of their products and processes by adopting measures such as:

- Using sustainable materials, such as recycled or renewable raw materials.

- Optimizing production processes to reduce energy and resource consumption.

- Minimizing waste and emissions.

Digitization and Industry 4.0

Digitization is becoming increasingly critical for the mechanical industry. The IoT technology is gaining prevalence in mechanical factories, allowing companies to improve efficiency, reduce costs, and enhance product quality.

Mechanical companies can benefit from digitization by adopting measures such as:

- Implementing IoT technologies to monitor machinery and production processes.

- Utilizing big data analytics to improve decision-making.

- Implementing simulation systems to test new products and processes.

Challenges and Opportunities

The mechanical industry will face a set of challenges in 2023, including:

- Resource scarcity, such as raw materials and skilled labor.

- Intensifying global competition.

- The need to adapt to new market demands, such as the growing demand for sustainable products and services.

However, the mechanical sector also presents several opportunities, including:

- The growth of demand for sustainable products and services.

- The emergence of new technologies revolutionizing the industry.

- The increasing globalization of the market.

CpGrinding’s Role

CpGrinding, a company specializing in precision component manufacturing for various sectors, including aerospace, is well-positioned to address the challenges and capitalize on the opportunities in the mechanical industry in 2023.

Future Outlook

CpGrinding, specializing in precision component manufacturing for the aerospace sector, is optimistic about the prospects of the mechanical industry in 2023. We anticipate that the growth in demand for sustainable products and services, the emergence of new technologies, and the increasing globalization of the market will offer significant opportunities for mechanical companies. To capitalize on these opportunities, we will continue to invest in innovation, sustainability, and globalization.