CNC numerical control machines are special machine tools that use computerized numerical control; since the eighties they have been used for precision mechanical processing, becoming essential for all precision mechanic processing and industrial automation going on nowadays.

The most used CNC machines are: milling machines, lathes, welding machines, sheet metal cutting machines, punching machines and press brakes. Thanks to their extreme versatility, CNC machines are now also used in sectors such as carpentry, tailoring, upholstery and packaging.

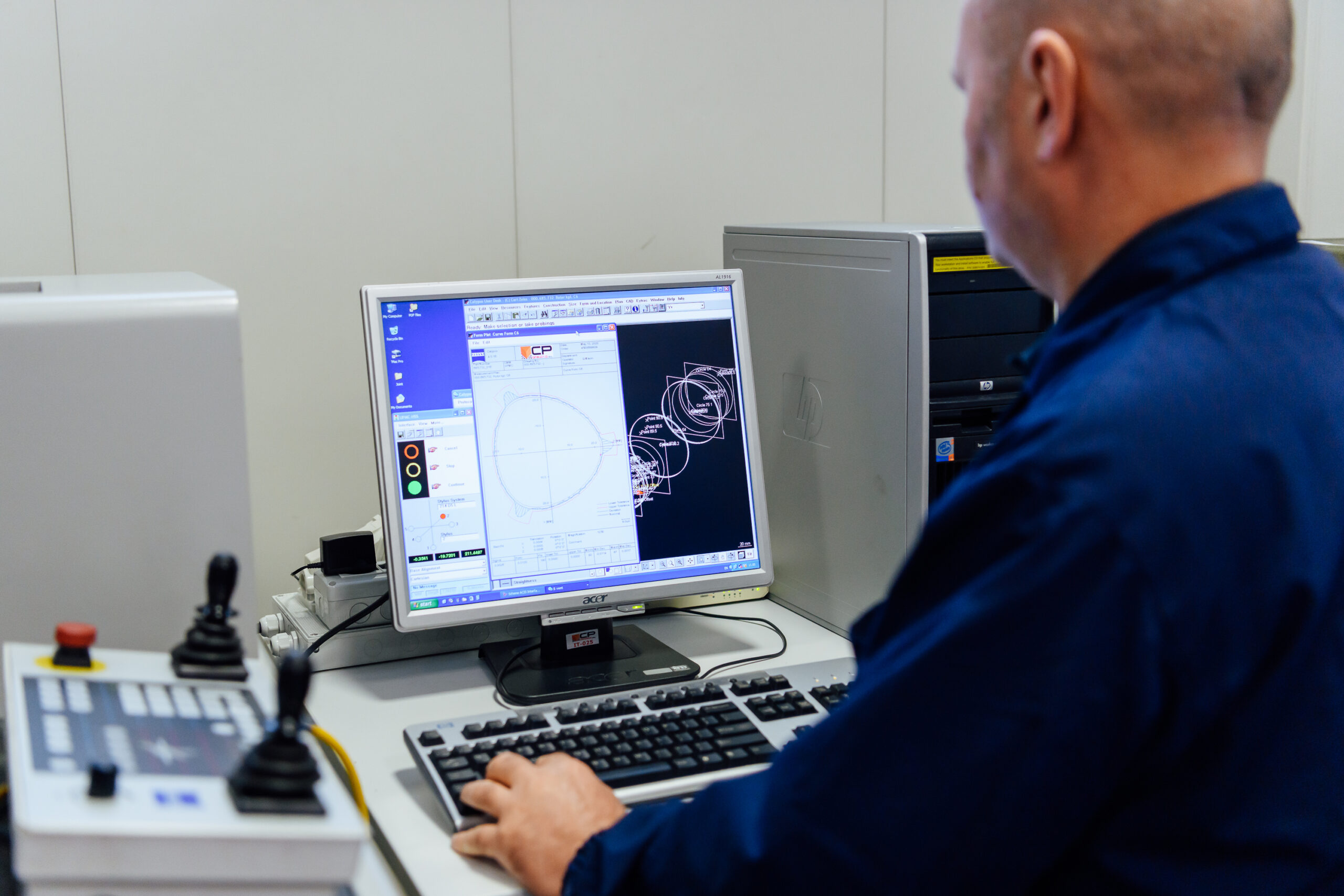

CNC machines reduce human intervention to a minimum; 90% of the processing is in fact carried out by the machine under the supervision of the operator whose intervention is limited in cases of malfunctions and failures, for this reason the CNC machines they are often used for series and continuous cycle productions.

Advantages of CNC machines:

CNC machines can bring a lot of advantages to precision mechanics and it’s not just about the reduction of human intervention; thanx to these machines it is in fact possible to control the whole processing remotely, using a computer, and achieve a quality of monitoring of processing impossible to reach with manual machines.

During the production phase, CNC machines allow you to increase and improve processing speed and precision but also repeatability, flexibility and adaptability.

The results that can be obtained thanks to CNC machining are always of the highest level: if properly configured, the best CNC machines for metalworking can produce identical pieces within a thousandth of a millimeter of tolerance (one micron, the thickness of about 4000 iron atoms).

The advantages of using CNC machines are amplified when it comes to parts with large complex curved surfaces: in this case the gain in speed and precision compared to manual production is unbridgeable.

Contact us for more information:

+39035940042