Augmented reality (AR) and virtual reality (VR) are revolutionizing the approach to design and production of components in the modern manufacturing industry.

These technologies offer new ways to visualize, design, and interact with components, bringing innovation and significant improvements to production processes. In this article, we will explore the application of augmented reality and virtual reality and their impact on the design and production of components.

The market today

The global AR and VR market in the manufacturing industry is projected to grow from $3.5 billion in 2020 to a staggering $16.8 billion by 2028 (MarketsandMarkets).

80% of manufacturing companies using AR and VR have reported increased productivity efficiency (PwC).

70% of manufacturing companies using AR and VR have reported a reduction in production costs (IDC).

Applications of Ar and Vr in design

AR and VR technologies offer a range of innovative applications for component design, revolutionizing how engineers conceive, develop, and test their projects. Here are some examples of how AR and VR can be used in design:

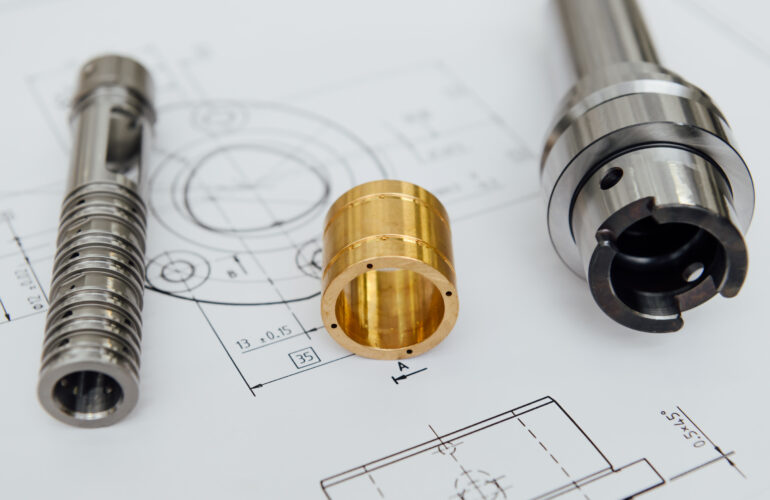

- Component Visualization: AR allows the visualization of 3D models of components in real scale superimposed on the real environment, facilitating the assessment of dimensions, characteristics, and interactions with other components.

- Remote Collaboration: VR enables engineers to collaborate on design projects in real-time, regardless of their geographical location.

- Assembly Simulation: AR can be used to simulate component assembly, identifying potential issues and optimizing the process.

Use of AR and VR in production

AR and VR technologies also open up new frontiers in the field of production, offering innovative solutions to improve efficiency, safety, and quality in production processes.

- Training: AR and VR can create realistic and interactive simulations for staff training on operational procedures, enhancing safety and productivity.

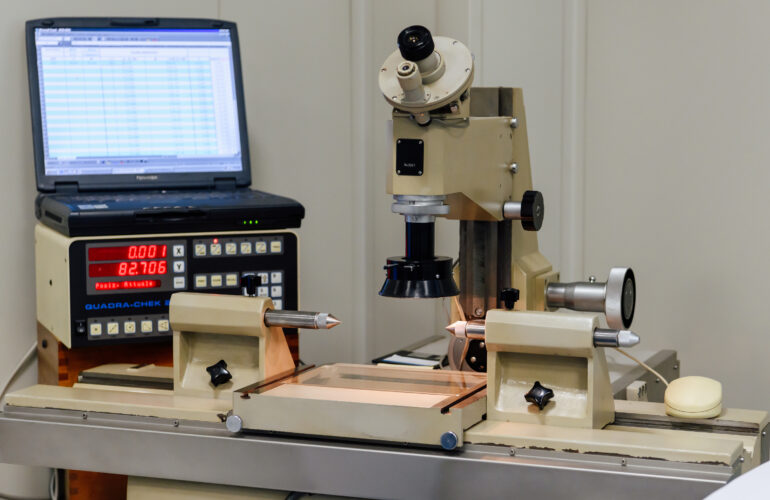

- Quality Control: AR can be used to overlay work instructions and 3D models onto real components, guiding operators during the production process and facilitating defect identification.

- Predictive Maintenance: VR can be used to create virtual models of machinery and components, allowing for the simulation of failures and optimization of preventive maintenance.

The future is here

Augmented reality and virtual reality offer enormous potential to improve the design and production processes of precision components. The adoption of these technologies is increasing and is expected to continue growing in the coming years, driving a significant transformation in the manufacturing sector.

t’s not just technological evolution; it’s a real transformation in how components are designed and produced. The future of precision mechanics is already here, and it is intertwined with augmented and virtual reality.