The aerospace industry is notoriously demanding in terms of precision and reliability, and precision mechanics plays a critical role in the design and production of aerospace components.

From turbine blades to landing gear parts, precision mechanics is essential to ensuring that components function safely and efficiently.

One of the most obvious examples of the importance of precision mechanics in the aerospace industry is represented by turbine blades, which convert the energy from fuel into rotational motion to spin the engine turbines.

The blades must be extremely precise and durable to withstand the extreme temperatures and forces generated by the high speed and elevated temperatures of the exhaust gases. Even a slight inaccuracy can cause significant damage to the turbine and jeopardize passenger safety.

Precision mechanics also plays an important role in the production of landing gear parts, which must be sturdy and reliable to support the weight of the aircraft during takeoff and landing.

The actuators and valves used in landing gear control systems require extreme precision to ensure that they function reliably in all flight conditions.

Quality control and maintenance

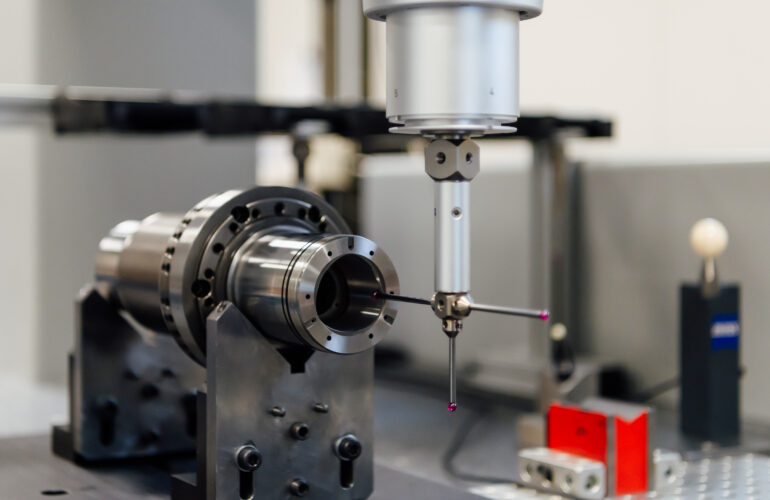

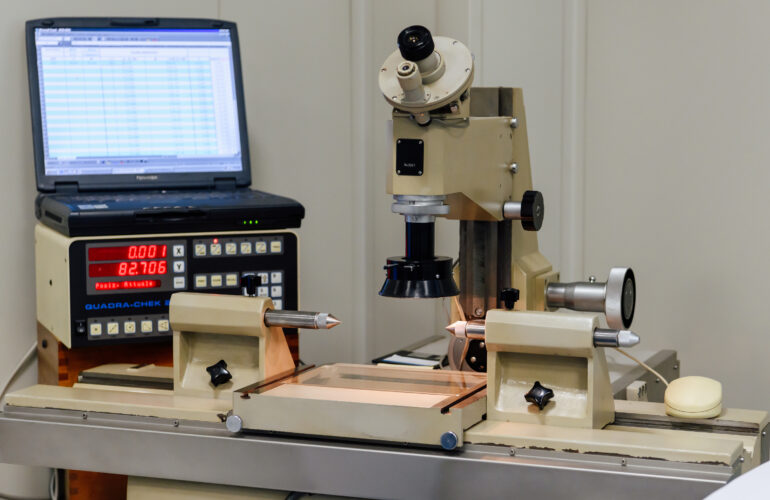

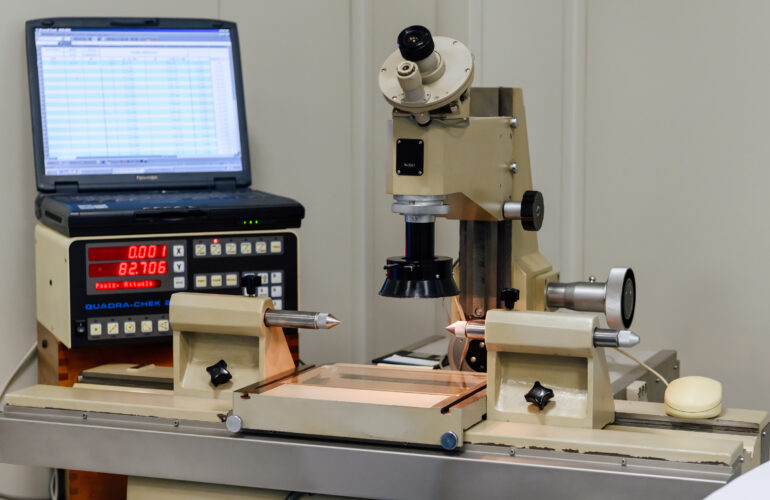

In addition to the design and production of components, precision mechanics is also used in many other areas of the aerospace industry, such as quality control, maintenance, and repair.

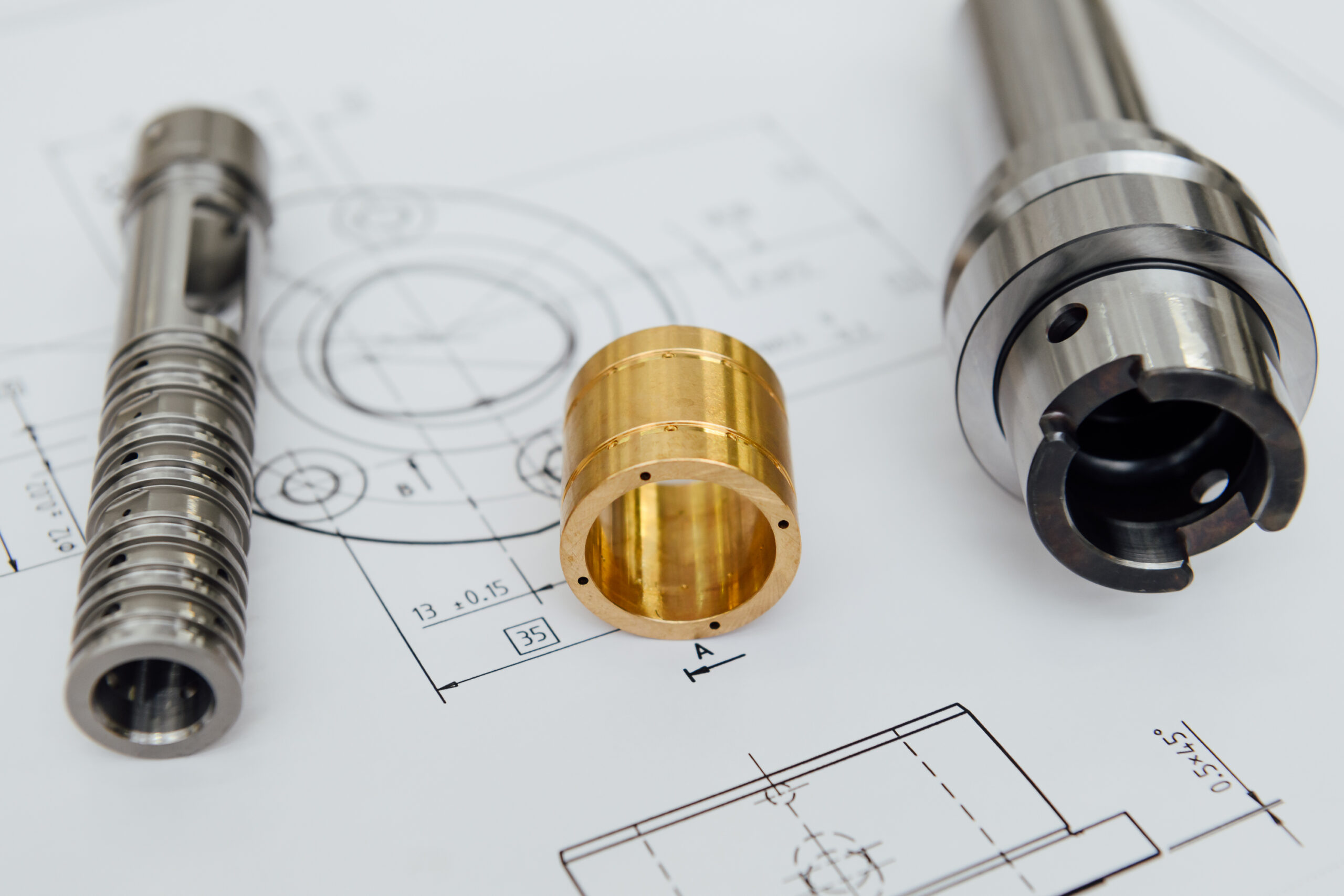

For example, precision measurement equipment is used to verify the tolerances of parts during production and to ensure that they meet the specific requirements of aircraft specifications.

In conclusion, precision mechanics plays a crucial role in the aerospace industry, ensuring that components are produced to the highest possible quality standards.

The combination of advanced production technologies and the expertise of precision mechanics professionals allows the aerospace industry to produce safe, efficient, and reliable aircraft that meet the needs of airlines and passengers.