The use of stones and other natural abrasives to process materials such as metals has been widespread since ancient times, just think of the smoothing operations that were carried out in ancient Greece.

These operations are the basis of what we now call grinding, that is: ” Grinding, the most important abrasive application, is in some way involved in the manufacture of almost every product. This use may be direct, as when the product requires pieces that must be made within close dimensional tolerance limits, or a very smooth surface, or when used on materials too hard to be machined by conventional cutting tools; or indirect, as when, for example, grinding wheels are used to sharpen cutting tools. The materials that are used to make cutting tools must of course be hard in order for the cutting tool to cut and retain its sharp edge. Abrasive grinding wheels are the only means for sharpening the dull edges of such tools.” From Britannica

The first grinding machine was invented around the mid-1800s when the metallurgical industry experienced an unprecedented development. While this industry was progressing, new techniques were needed for processing materials that could no longer be carried out by hand. These requirements led to the design and construction of the first grinding machines

Some documents show that Leonardo Da Vinci worked on the design of a technology for grinding with automatic advancement and discharge of needles to be rectified.

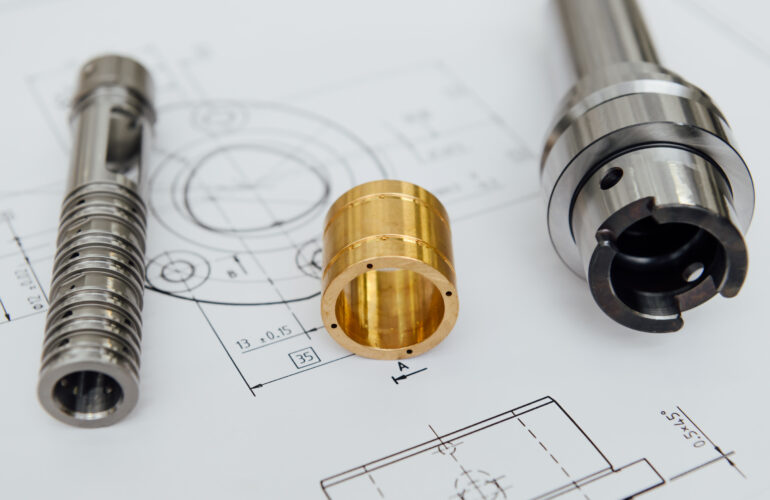

Grinding nowadays

The modern definition of Grinding Machine, according to Britannica says: “grinding machine, tool that employs a rotating abrasive wheel to change the shape or dimensions of a hard, usually metallic, body.

All of the many types of grinding machines use a grinding wheel made from one of the manufactured abrasives, silicon carbide or aluminum oxide. The wheel is manufactured by mixing selected sizes of abrasive granules with a bonding agent (such as clay, resin, rubber, shellac, or silicate of soda) and fusing them together by baking or firing. The grade (hardness) of a wheel is determined by the ratio of bond to abrasive. Properly, a grinding wheel is self-sharpening because as it is worked, the dull grains break off, exposing fresh, sharp grains. The harder the grade, the more slowly the wheel releases the grains.”

It is precisely thanks to that it is possible to obtain the optimal shape or surface state, ensuring a final result with a very high degree of precision.

Contact us for more information.