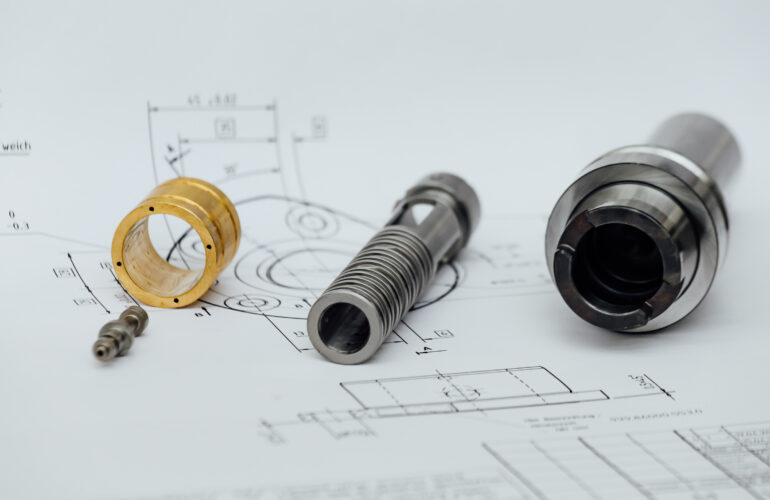

In cases of wear or collision in which the exact coupling of the tool holder cone is lost, resulting in a lack of precision and repeatability of the machining, It’s necessary to perform and an ISO union taper seat restoration and grinding.

Usually, one of the most frequent problems concerning machine tools, is that of the cone’s damage, where the tool-holder spindle is housed.

Before proceeding with the tool holder cone grinding, the geometric conditions of the spindle line, the collet pulling strokes and the tool holding force are checked and more analysis are carried out to understand if it is possible to restore the ideal conditions of the spindle cone so that it can go back to the ideal performance.

The grinding of the spindle cone in the machine restores the original tolerances and roughnesses and corrects the malfunctions caused by wear and impacts.

The grinding of a spindle cone is an operation that can be performed on all CNC machine tools.

After grinding the spindle cone, we proceed with the execution of some tests aimed at verifying the coupling of the spindle cone with certified plugs, check the tightening of the tool clamping collet and measure the tool holding force.

At CpGrinding we deal with the grinding of spindle cones, providing technical assistance on all the main CNC machine tools. Contact us for more information.

+39 035 940042