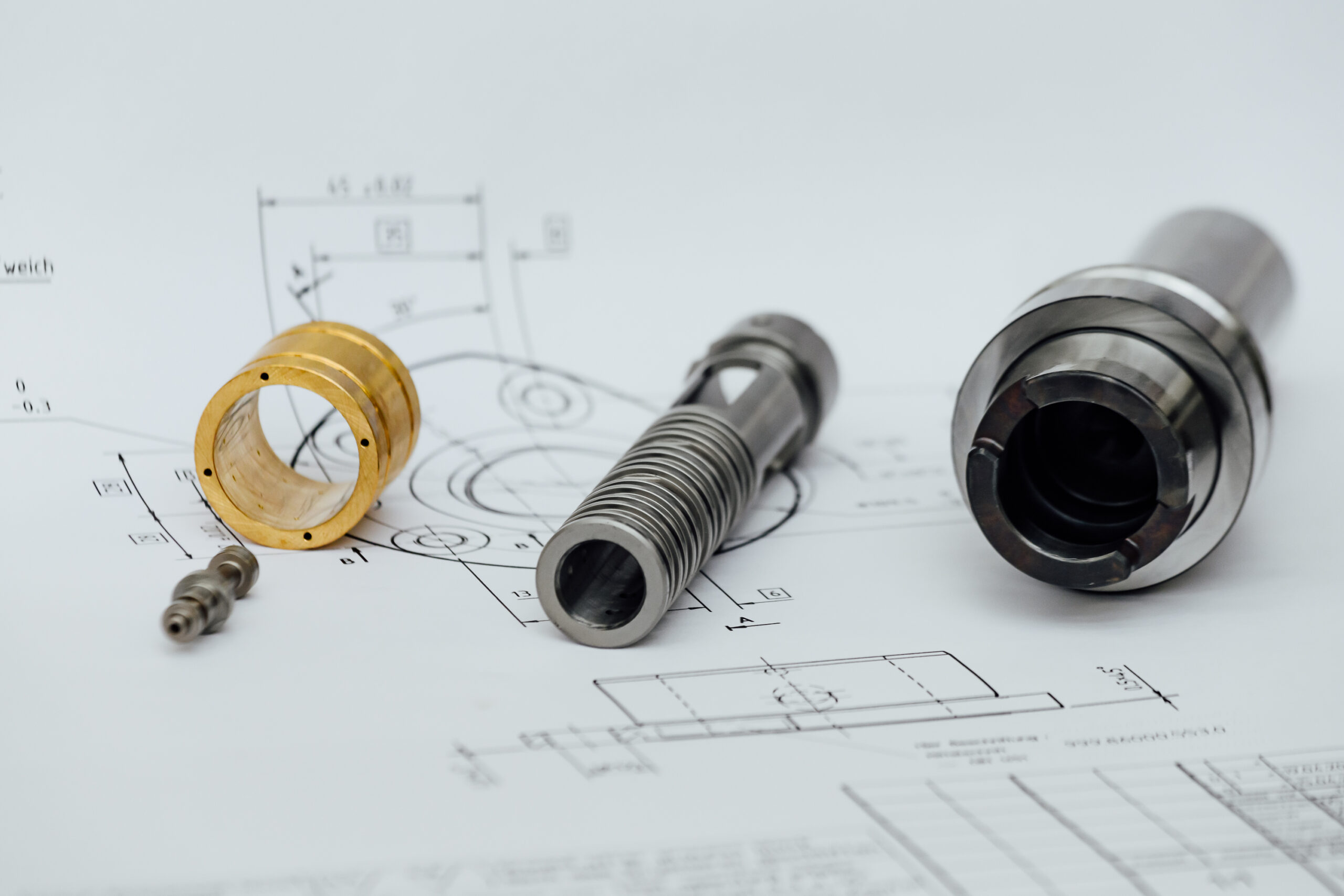

In precision mechanics, the tool-holding systems is a fundamental dowel for any production. The tool-holding systems, i.e. the connection between the cutting tool and the machine spindle, is in fact crucial to achieve full productivity and efficiency.

Specifically, the tool-holding system is the part that:

- is handled by the tool exchanger

- holds the tool in its own storage

- allows insertion into the spindle

- contains magnetic pads for storing tool data

The different types of tool-holding systems are:

- ISO connection

conical: tool

low speeds

- HSK attack:

interlocking

high speeds

There is not one tool-holding system is suitable for all applications as for example if tool-holding system is designed to perform high speed finishing operations it will not be suitable for other procedures such as roughing. Using an unsuitable tool-holding system can also lead to dimensional errors or excessive wear of the spindles.

Therefore every machining requires a particular type of tool-holding system

Our offer

At CpGrinding we produce and process tools in different types

(adapters, extensions, reductions) with the following connections:

CAPTO/PSC profile (male and female) from C3 to C10

HSK from 32 to 100

ISO 20 to 60.

Contact us for more information.