Rotondimeters are instruments used in precision mechanics to accurately measure angles. Angles are crucial parameters in mechanical applications, such as machine alignment, equipment adjustment, component assembly, and design specification verification.

Operation of Rotondimeters

Rotondimeters employ a combination of mechanical and optical devices for angle measurement. A traditional rotondimeter consists of a graduated disk with a pointer and an optical magnification system. The pointer is positioned on the angle to be measured, while the operator uses the optical system to read the value on the graduated indicator.

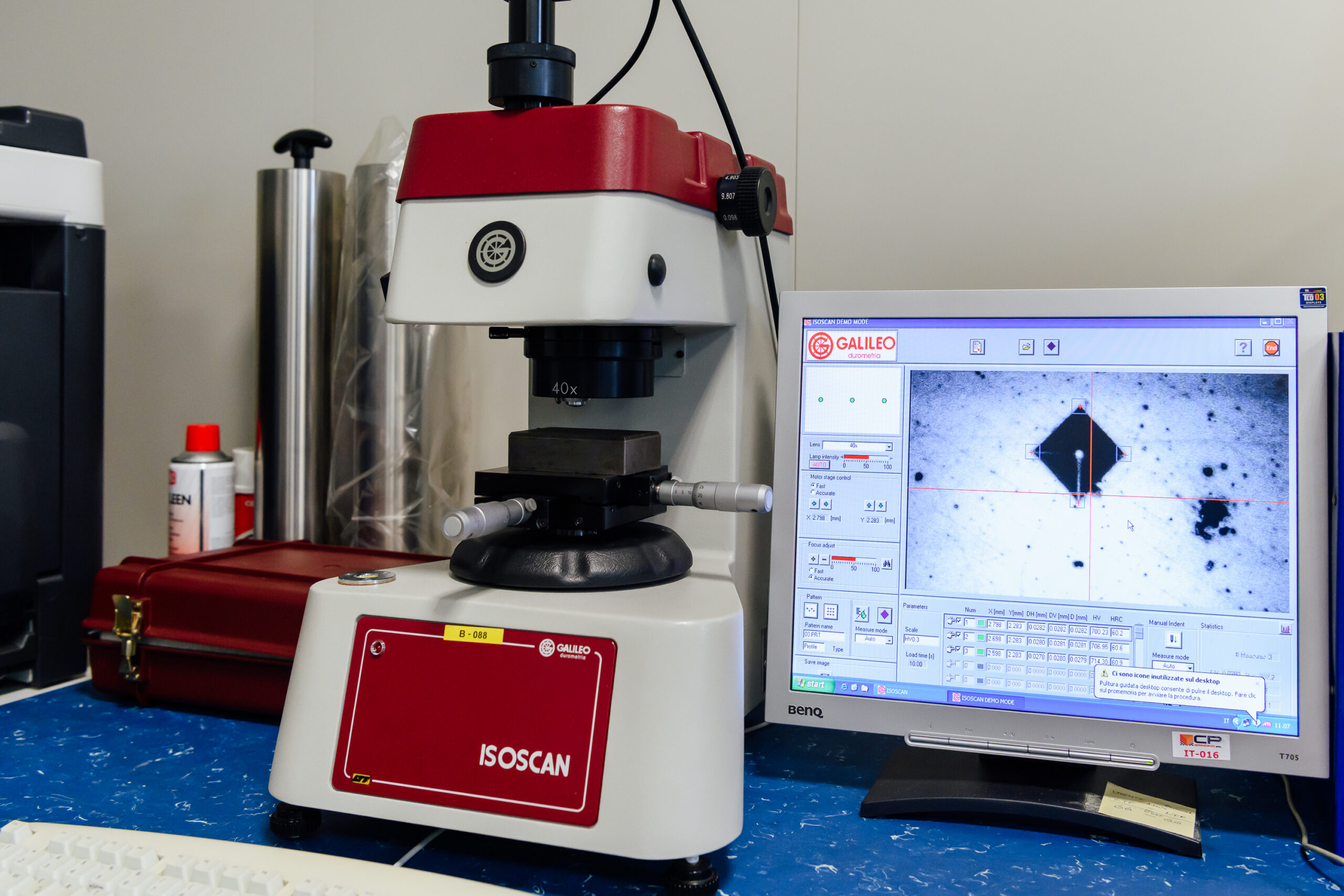

In recent years, digital rotondimeters have become increasingly common. These instruments utilize electronic sensors to measure the angle and provide an accurate digital reading. Digital rotondimeters often offer additional features such as the ability to store measurements or transmit data to a computer or control system.

Precision and Calibration

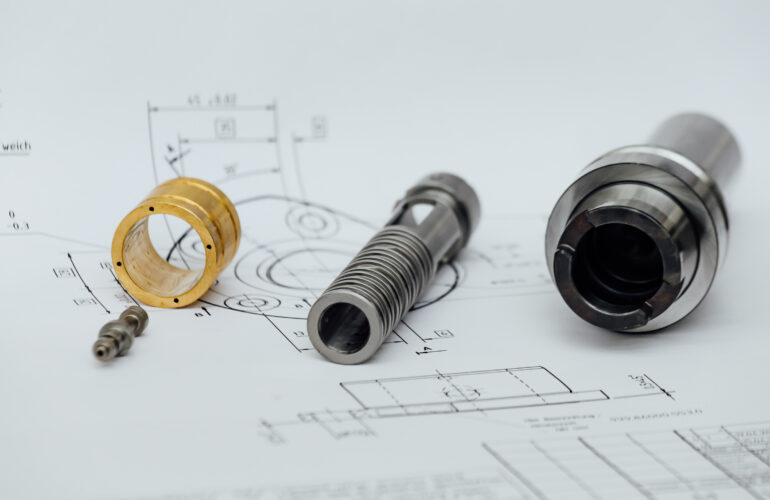

In precision mechanics, the accuracy of angular measurements is crucial. Rotondimeters must be constructed with high-quality materials and precise measuring mechanisms to ensure accurate results. The moving parts of rotondimeters should slide without friction or play, while gears and bearings should be manufactured with tight tolerances.

Calibration is an important step in the process of using rotondimeters. Rotondimeters need to be adjusted and periodically verified to ensure measurement accuracy. This can be done using reference blocks with known angles or specialized calibration devices. Regular calibration ensures that rotondimeters maintain their accuracy over time.

Applications in Precision Mechanics

Rotondimeters have a wide range of applications in precision mechanics. They are used to measure alignment angles, tilt angles, rotation angles, and opening angles. They can be employed in machinery installation, mechanical component control, instrument adjustment, and device assembly.

The accuracy of angular measurements is crucial to ensuring the proper functioning of mechanical components and compliance with design specifications. Rotondimeters allow operators to obtain accurate and repeatable measurements, reducing errors and increasing work efficiency.

Conclusion

Rotondimeters are essential tools in precision mechanics for accurate angle measurement. Their high-quality construction, measurement precision, and periodic calibration ensure reliable results. Thanks to rotondimeters, operators can achieve high precision in angle measurement, ensuring the proper functioning of mechanical components and adherence to design specifications.