In mechanical processing, grinding is a procedure performed with a machine called grinding machine. Grinding is used to bring any component to the state of optimal shape or surface of the project, ensuring that all residues and excess material are eliminated, guaranteeing a high degree of finish to the machined surface.

Types of grinding machines

Grinding machines, which have a fine-grained and extremely hard grinding wheel as their tool, are divided into three types:

- Cylindrical grinder

- Centre grinder

- Surface grinder

Cylindrical grinder

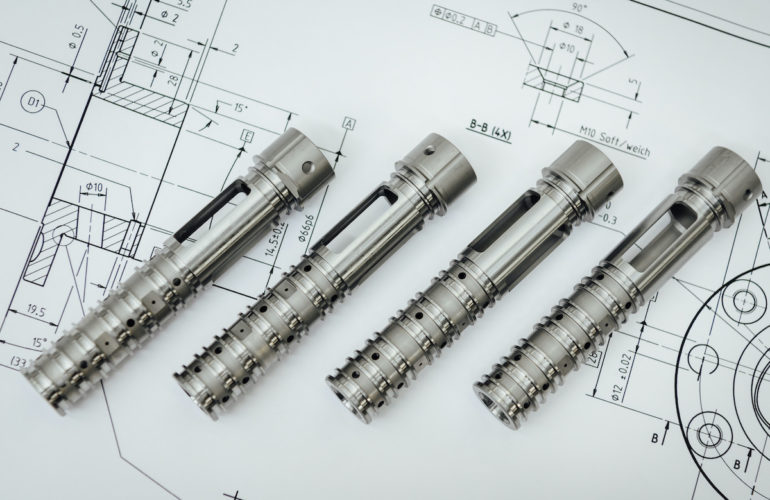

Cylindrical grinder include both the types that use centers and the center less types. A cylindrical grinder may have multiple grinding wheels. The work piece is rotated and fed past the wheel(s) to form a cylinder. It is used to make precision rods, tubes, bearing races, bushings, and many other parts.

Centre grinder

Centre grinder, which is usually employed as a machining process when manufacturing all kinds of high-precision shafts. The primary function of these machines is to grind the centers of a shaft very precisely. Accurate round center holes on both sides ensure a position with high repeat accuracy on the live centers.

Surface grinder

The most common surface grinders have a grinding wheel rotating on a horizontal axis cutting around the circumference of the grinding wheel. This type of machine removes large amounts of material and grinds flat surfaces with noted spiral grind marks. It can also be used to make and sharpen metal stamping die sets, flat shear blades, fixture bases or any flat and parallel surfaces.

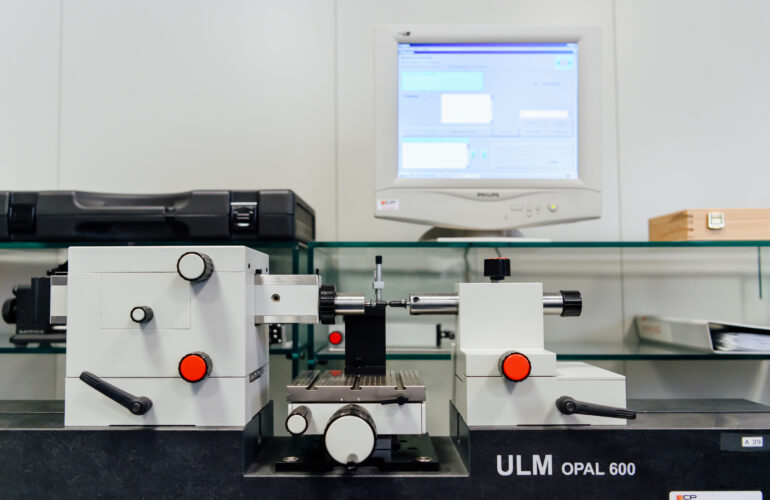

In the field of precision mechanics, it is precisely during the grinding phase that the component reaches the optimal state of shape or surface, ensuring a final result with the highest degree of precision.