Grinding can be done using different methods and the experience of an experienced rectifier to know which processes and techniques will produce reliable and durable parts.

The skills and expertise needed to understand the combined effect of different factors on the grinding process and how they affect the finished job, are critical to producing robust and reliable parts.

One of the most important techniques we use to achieve these results is dynamic balancing which helps to obtain accurate results on complex or asymmetrical parts that cannot be statically balanced.

Accurate dynamic balancing is critical as if a small part is out of balance, the whole set up is at risk. Correct balancing allows parts to be ground within the correct working rotation speed and within the designed tolerances.

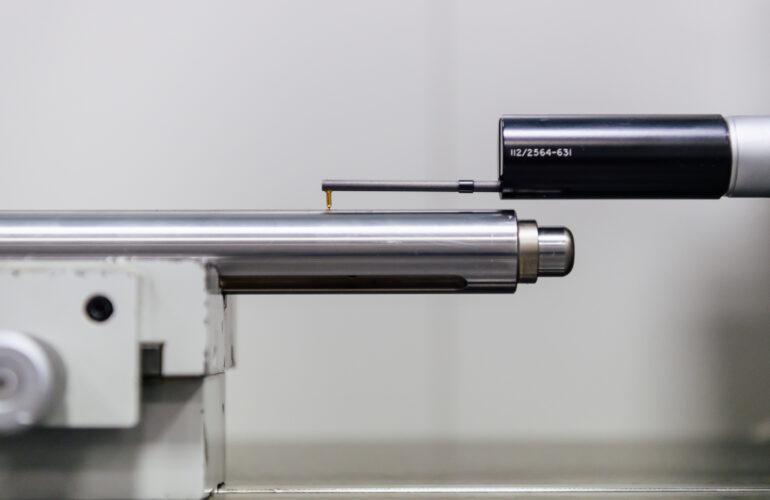

How to achieve dynamic balancing in precision grinding operations

Dynamic balancing can be applied to both tools and mechanical components and ensuring that both are properly balanced during grinding processes ensures smooth operation.

When it comes to precision grinding, the static equilibrium refers to the state in which the center of gravity of an object is on its axis of rotation. When stationary in the machine, gravity does not move the part around its axis when it is rotated to a certain position.

Dynamic balancing takes into account the asymmetrical characteristics of the piece by applying counterweights and adjusting the number of grinding revolutions to maintain the position of the piece and eliminate vibrations or vibrations.

At CpGrinding we are specialized in precision grinding and with many years of experience we are able to guarantee the highest quality and performance even of critical parts.

Contact us today to talk to our experts and find the right solution for your needs.

+39 035 94004