Corrosion is a chemical process that causes the gradual deterioration of a solid substance, mostly a metal, due to external agents.

Corrosion is a natural and irreversible process with electrochemical nature and it determines a chemical-physical interaction of metals with the surrounding environment.

The process of corrosion can be avoided by using specific interventions such as anti-corrosive heat treatments that are part of the so-called passive anti-corrosive treatments.

Passive anti-corrosive heat treatments put a stop to corrosion by exploiting a passive type of protection in which protection serves to insulate the metal’s surface from the external environment.

Anti-corrosion treatments that can be applied on mechanical parts

When it comes to mechanical partes, several anti-corrosion treatments can be used. The most common are:

- Galvanic process: this process sees the galvanization of the component and a passivation bath in order to create a metal cover to protect the component from external agents and chemical aggressions.

- Organic polymers: by this process the component is covered with organic polymers that protect it from external aggression.

- Zinc plating: the component is immersed in a zinc bath; the oxidation proceeds on the zinc and the iron will remain protected until the zinc is consumed.

- Chromium plating: the component is coated with a thin layer of chromium that is applied electrolytically.

- Cathodic coating by immersion: this system is obtained by connecting the protective film to a cathode to ensure that it is attracted electrolytically to the metal of the component.

Our solutions

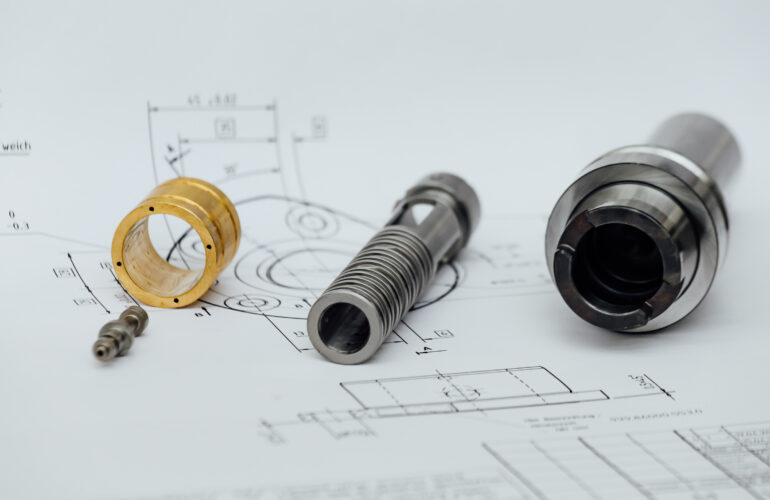

For what particularly concerns the production of all types of tool holders and shanks attached to milling machines, cutting centres and high speed cutting centres (HSC) not only for the steel and light alloy industries but also for the processing of other materials such as wood, marble and glass, each single part manufactured is compliant to the DIN 2080, DIN 69871, MAS 403 BT, DIN 69893-5 /HSK standard provisions. The tool holders we produce furthermore feature specific anticorrosion heat treatments and assorted balancing techniques relating to high speed.

Contact us for more information.